How Do Magnetic Grippers Used for Robots Unload & Sort Metal Cut Parts

If your manufacturing business involves steel plate cutting procedure, then you surely would have met such question as, how to unload these small metal laser cut parts and sort them in a more quick and efficient way. Below, we’ll show you the advantages of magnetic grippers used for robots, in handling small metal cut pieces.

Robot with magnetic gripper, how does it work?

Magnetic robot gripper provides safe gripping of ferromagnetic workpieces by using the magnetic field of integrated magnet materials. Electrically switched, strong magnetic force, make it easier to handle complex laser-cut ferromagnetic workpieces over other grippers.

See for yourself how customized magnetic grippers used for robots, perform in real material handling process.

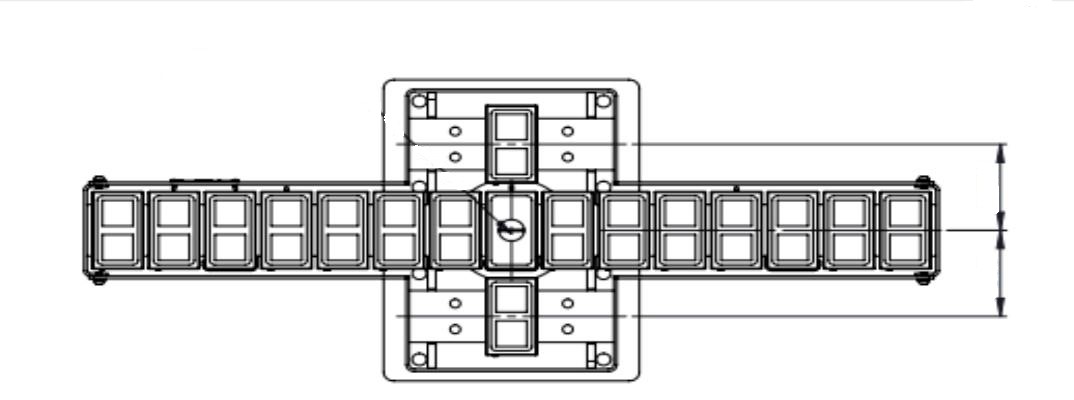

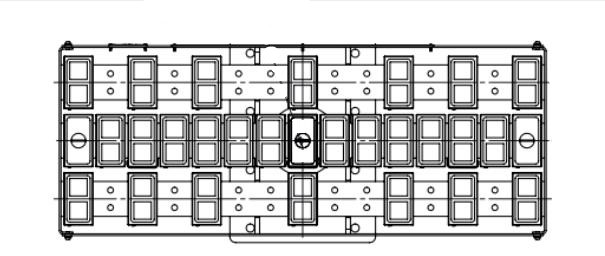

Cartesian robotic system: Unloading cut parts of varying sizes and shapes, 1pc each time off the laser cutting table; transferring it onto the conveyor belt for the next sorting procedure.

Robotic arm gripper: Steel cut parts being absorbed and picked up by magnetic force of the gripper, to be sorted into different pallets.

Our magnetic gripper used for robots are capable of adsorbing a great variety of ferromagnetic pieces, like the metal cut parts, with different geometries and properties.

With HVR MAG’s custom designed & manufactured magnetic grippers used for robots, you will:

- Handle with reliability and safety – strong electro permanent magnetic holding force, whichguarantees grasping of the workpiece even when the power is shut off.

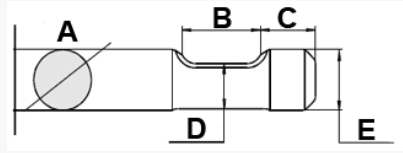

- Get great usage flexibility – Adjustablemagnetic gripping force by utilizing different small magnet gripping heads.

- Less energy consumption – No power consumed in gripping state

In applications, where vacuum grippers are not performing efficiently, e.g. due to porous or uneven surfaces, HVR MAG will do the task. Magnetic grippers used for robots, can be customized for applications in other manufacturing lines, like the above mentioned – holding workpieces with holes such as those handled in laser cutting operations. Moreover, they are also suitable for loading irregularly shaped large steel frames for welding process, and for transferring uneven surfaces in palletising/depalletising systems. Learn more about our gripping solutions for robotics, welcome to visit our website: https://www.hvrmagnet.com/category/magnets-for-industiral-automation-5.html