Robotic Welding Fixture Magnet: HVR MAG

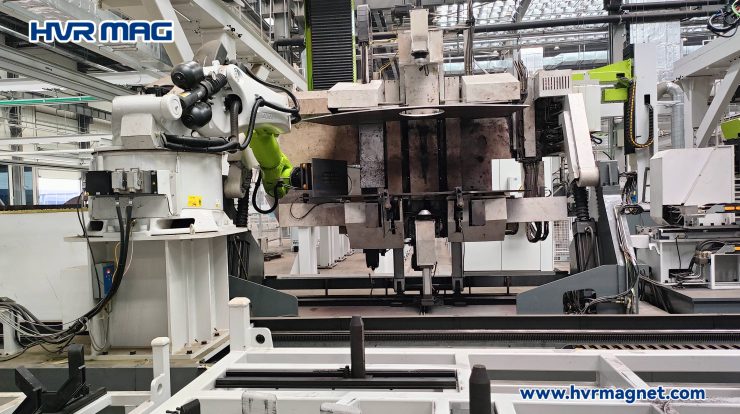

Electro-permanent Magnet in Robotic Welding Clamping System

In the wave of smart production upgrades of Industrial 4.0 and Made in China 2025, more and more smart manufacturing factories are emerging. The robotic welding fixture magnet is one of the important elements of automated production preparation. Manufacturers have paid more and more attention to robotic workholding fixtures.

Traditional welding fixtures are generally applicable to manual welding, loading, and unloading. But they cannot meet the requirements of industrial automation. While magnetic welding jigs for automation can not only accurately position the workpiece, but also greatly shorten the welding processing time and accelerate the effectiveness of the whole manufacturing process!

The main performance of the HVR Magnetic welding clamps for robotic welding system:

1. Magnetic welding fixtures can accurately and stably position and clamp the workpiece. It reduces the size deviation of the products and improves the accuracy of the manufactured parts. Besides, magnetic welding jigs can prevent or reduce welding deformation, and improve welding efficiency.

2. With small space occupation and highly flexible adaptation to various welding robots and working stations, magnetic welding positioners can clamp the workpieces on the designated area with strong magnetic clamping force. So the process defects are reduced, and welding quality is improved and stable.

3. It replaces the heavy manual work of positioning, clamping, and workpiece turning required for parts assembly, improving labor conditions and productivity.

4. Custom design and manufacturing. For the assembly process of certain welding assemblies, magnetic welding clamps are usually custom-made to your specific needs.

HVR MAG has already custom-made magnetic welding fixture magnets for many smart workshops (Click to know the on-site application). We also believe the robotic welding fixture magnet in the field of intelligent manufacturing is becoming more and more popular. HVR MAG hopes to contribute to the automated welding clamping through its professionalism in the electro-permanent magnet. Our magnetic solutions cover not only robotic automation but also lifting solutions for steel structural fabrication and machinery, quick mold change for plastic injection molding, and working holding chucks for lathe and CNC machining. If you’re interested in business collaboration, please e-mail us at: export@hvrmagnet.com