Manufacturing with Electro Permanent Magnetic EOAT

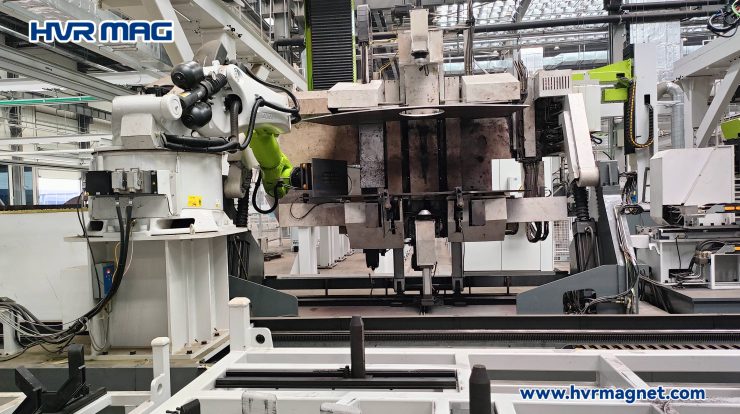

In the ever-evolving field of construction machinery manufacturing, technological advancements continue to shape the industry’s landscape. One such innovative solution that has gained prominence is Electro Permanent Magnetic End-of-Arm Tooling (EOAT). This cutting-edge technology offers numerous advantages in terms of efficiency, adaptability, and safety. In this article, we will explore the significant role of electro permanent magnetic EOAT in revolutionizing construction machinery manufacturing processes.

Enhanced Efficiency and Convenience

The utilization of electro permanent magnetic EOAT in construction machinery manufacturing streamlines the handling of steel plates. With a simple and swift lifting process, it eliminates the need for laborious manual prying or clamping. This streamlined approach significantly reduces the time spent on traditional handling methods, boosting overall efficiency and productivity. Moreover, the improved speed and convenience reduce labor intensity, resulting in a safer and more pleasant working environment.

Adaptability to Various Workpiece Sizes

Construction machinery manufacturing often involves working with steel plates of different sizes and thicknesses. Electro permanent magnetic EOAT tackles this challenge with ease. Its adaptability enables effortless handling of various workpiece sizes, allowing manufacturing processes to proceed smoothly without delays or disruptions. With the flexibility to lift and manipulate different specifications of steel plates, the EOAT optimizes workflow and enhances manufacturing efficiency.

Preventing Damage and Ensuring Quality

When dealing with delicate materials like steel plates, avoiding surface damage or deformation is crucial to maintaining the quality of the final product. Electro permanent magnetic EOAT provides a solution by generating a powerful magnetic force to securely hold the steel plates during handling. This eliminates the risk of surface damage caused by clamps or other traditional gripping mechanisms. By safeguarding the integrity of the workpieces, the EOAT contributes to the production of high-quality construction machinery.

Seamless Integration with Gantry Crane

Construction machinery manufacturing often involves the use of overhead gantry cranes for material handling. Electro permanent magnet easily integrates with these cranes, enabling seamless coordination between lifting and transportation processes. This integration not only reduces labor costs but also enhances overall operational efficiency. By automating the loading and unloading of steel plates, the magnet eliminates manual intervention, reducing the risk of accidents and increasing productivity.

Conclusion

Electro permanent magnetic EOAT has emerged as a game-changer in construction machinery manufacturing. Its ability to enhance efficiency, adaptability, and safety revolutionizes the industry. The technology’s convenience and efficiency in handling steel plates, adaptability to various workpiece sizes, prevention of damage, and seamless integration with crane operations prove its worth in the manufacturing processes. As the construction machinery sector continues to evolve, electro permanent magnetic EOAT serves as a vital tool, driving progress and enhancing productivity in this dynamic industry.

For more information, please contact HVR MAG at export@hvrmagnet.com