Identifying A Hydraulic Breaker From Its Demolition Tool

Keywords: bobcat hydraulic hammer, hydraulic breakers for excavators

One of the most common calls we receive at Gorilla is a request to identify an unknown hydraulic breaker so that our customer can acquire parts or a tool. As hydraulic hammers have a difficult life, the identification tag is often missing, or the information has been “sanded off” from use. Locating actual stamped serial numbers on a hydraulic breaker is often difficult due to debris and wear, and those are often difficult to interpret on their own. Further, there are many hydraulic hammers that are auction only(see previous blog) that no matter what you can find, there is no support to reach for in the United States.

What You Should Be Keen Of

In these cases, we need photographs of all visible sides of the hydraulic hammer you are trying to identify. This will tell us the overall hoeram’s design as well as its color. Color does not sound like much, but hydraulic hammer manufacturers typically stick to specific colors for their various generations, so this is a help in narrowing down the hydraulic breaker make and model. Sometimes just photos of the breaker and an accurate measurement of the hammer steel’s diameter as it comes out of the lower bushing is enough to identify the hammer.

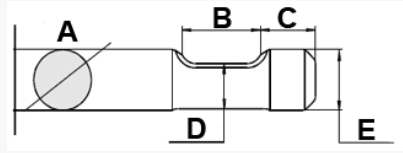

However, in most cases the demolition moil tool must be removed from the breaker. There are hundreds of different tool prints/shanks from over one hundred known hydraulic breaker manufacturers, with only millimeters separating one print, or tool shank, from another. The shank is the part of the demolition tool that goes into the tool holder, front head or chuck housing. If you go to our measuring guide(on our site), you will likely find the general shape of your hydraulic hammer chisel there.

Accurately Measuring and Identifying

As this comes down to millimeters, a tape measure is pretty useless. The only tool that will provide this accuracy is a digital caliper-or an analog caliper and a well trained technician. Each round diameter of the hydraulic breaker or hoeram steel must be measured as well as the thickness between the two tool retainer slots, or the thickness between a single retainer slot and its opposite diameter.

Once you match the drawing of your hammer point to one from our tool bit measuring page, (refer to), you may send along your drawing to sales@gorillahammers.com for a member of our Gorilla team to try to match it up to one of the hydraulic hammers we can support so that we can provide a replacement hydraulic hammer demolition tool or provide a parts drawing. With proper cooperation, our Gorilla team has been successful in identifying many breakers each year, but we are totally reliant on our customers providing accurate information of each dimension measured with the right tools. Freight is expensive on these often very heavy toolbits, so please double check all measurements.

Contact Gorilla Hammers Today

If you need help identifying your hydraulic hammer and/or have questions about the identification process, please contact the Gorilla Hammers team at 1 (888) 814 – 6745 for assistance.

Example One

Example Two

Example Three

Example Four

Example Five

Example Six

Example Seven

Example Eight