Magnetic Grippers for Industrial Automation

Magnetic Grippers for industrial automation play an important role in handling and manipulating objects. Magnetic grippers use magnetic forces to hold and release objects, making them an efficient and reliable solution for various industrial applications.

Electro-permanent magnetic grippers for industrial automation

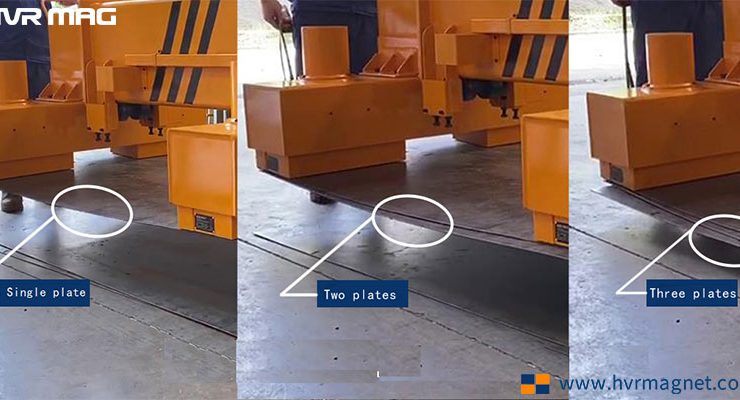

Electro-permanent magnetic grippers for industrial automation are by far the most recommended type. Electro-permanent magnetic grippers use a permanent magnet to hold and release objects. Power is only used to change the direction of the magnetic field, making them very energy efficient. They are simple in design, easy to use and have a long service life. Electro-permanent magnetic grippers come in a variety of shapes and sizes to suit different types of objects. They can be used in pick-and-place applications, assembly lines and material handling systems.

HVR MAG, as a specialist manufacturer of electro-permanent magnetic grippers, has three series of magnetic grippers. They are used for mounting on articulated robot, gantry robot and automated welding machines. Many of our customers have completed line conversions using these magnetic grippers for industrial automation and have seen very significant improvements in safety and productivity.

If you have small steel workpieces that require a robot to pick up, inspect, palletise and transfer them, a articulated robot mounted with magnetic grippe is usually the recommended choice. The articulated robot is more flexible and the magnetic gripper works well with the robot to grip, release or flip the workpiece. For large steel workpieces and simple tasks such as horizontal gripping for transfer, palletising or packaging, gantry robot with magnetic gripper is the best option. When welding steel, the magnetic gripper can be used to hold the workpiece in place, allowing truly automated welding. As long as care is taken to maintain a distance of approximately 5 cm between the weld opening and the contact surface of the magnet, the weld will not be affected.

What Can Magnetic Grippers Do in Industrial 4.0?

In industrial 4.0, magnetic grippers can play a crucial role in improving productivity, efficiency, and safety. Magnetic grippers can be integrated into robotic systems, allowing for flexible and autonomous handling of objects. This can reduce the need for manual labor, increase throughput, and improve the quality of the final product.

Magnetic grippers can also be used in material handling systems, allowing for efficient and reliable transfer of materials between different processes. This can reduce material waste, minimize downtime, and improve overall system performance.

In addition, magnetic grippers can improve safety in industrial environments. They can be used to handle hazardous materials or objects that are too heavy or awkward for human operators to handle safely. This can reduce the risk of accidents and injuries in the workplace.

Conclusion

Magnetic grippers are versatile and reliable workholding solutions that can improve productivity, efficiency, and safety in industrial automation. Different types of magnetic grippers offer different functions and advantages. In industrial 4.0, magnetic grippers can be integrated into robotic systems and material handling systems to improve performance and reduce human labor. Magnetic grippers can also improve safety by handling hazardous materials or heavy objects.

Feel free to contact us for more information about magnetic grippers for industrial automation.