EPM Steel Plate Lifting Magnet| Excavator magnet

epm magnet

Steel plate lifting magnet have revolutionized material handling operations, providing a safe and efficient solution for lifting heavy steel plates. Among the various types of lifting magnets, those made of electro-permanent magnets have gained significant popularity. In this blog, we will explore the benefits of steel plate lifting magnet that utilize electro-permanent magnets, highlighting how they enhance efficiency, safety, and productivity in various industries.

Superior Holding Power

Steel plate lifting magnets made of electro-permanent magnets offer exceptional holding power. These magnets combine the advantages of both permanent and electro magnets, resulting in a strong and reliable magnetic grip on steel plates. The electro-permanent magnet technology ensures that the lifting force remains intact even in the event of a power failure. This feature minimizes the risk of accidents, increases stability during lifting operations, and enhances overall safety.

Energy Efficiency

One of the significant benefits of electro-permanent magnet steel plate lifters is their energy efficiency. These magnets require electrical power only during the activation and deactivation phases. Once the magnet is engaged, it maintains its magnetic strength without consuming any additional energy. This energy-saving characteristic not only reduces operating costs but also promotes sustainability, making it an environmentally friendly choice for material handling operations.

Adjustable Magnetic Poles

Steel plate lifters with electro-permanent magnets offer the advantage of adjustable magnetic poles. This feature allows operators to precisely position and align the magnet with the steel plate, ensuring optimal contact and grip. The ability to adjust the magnetic poles enhances the lifting performance, enabling operators to handle plates of various sizes and shapes with ease and accuracy. This versatility significantly improves efficiency and productivity in material handling tasks.

Quick and Easy Operation

Electro-permanent magnet steel plate lifters are designed for quick and easy operation. With the use of a control panel or remote control, operators can activate or deactivate the magnets effortlessly. This feature reduces downtime between lifts, streamlines the lifting process, and increases overall productivity. Additionally, the ease of operation minimizes the physical strain on operators, promoting a safer and more comfortable working environment.

Reduced Risk of Damage

The precise control offered by electro-permanent magnet steel plate lifters reduces the risk of damage to both the magnet and the steel plates being lifted. The adjustable magnetic poles allow for accurate positioning, preventing unnecessary contact or abrasion between the magnet and the plates. This feature is particularly beneficial when handling delicate or high-value steel plates, ensuring their integrity and minimizing the need for repairs or replacements.

Versatile Applications

Electro-permanent magnet steel plate lifters are versatile tools suitable for a wide range of applications. They can handle various sizes and weights of steel plates, making them ideal for industries such as construction, manufacturing, shipbuilding, and steel fabrication. Whether it’s lifting plates for installation, transportation, or storage purposes, these lifters offer a reliable and efficient solution.

Conclusion: Steel plate lifting magnet made of electro-permanent magnets have become a game-changer in material handling operations. With their superior holding power, energy efficiency, adjustable magnetic poles, quick operation, reduced risk of damage, and versatile applications, these lifters enhance efficiency, safety, and productivity in various industries. By incorporating electro-permanent magnet steel plate lifters into material handling processes, businesses can optimize their operations, reduce costs, and create a safer working environment for their employees.

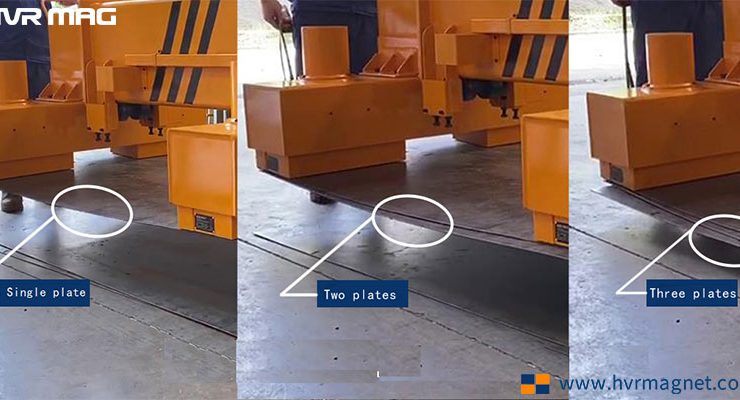

As a manufacturer of electro permanent magnetic lifting device. HVR MAG had developed several types of steel plate lifting magnet such as HM1 series for single plate handling, HM3 series for thin plate handling and HM6 series for multiple plates handling. Welcome to contact us for customized solution.

Related question

What is hydraulic magnet for excavator?

A hydraulic magnet for an excavator is an attachment that utilizes hydraulic power to generate a strong magnetic field for lifting and handling ferrous materials. It is typically mounted to the excavator’s arm or boom. The hydraulic magnet consists of a magnet assembly, which can be an electromagnet or a permanent magnet, and hydraulic components that control its operation. When activated, the magnet creates a powerful magnetic force, allowing it to attract and securely hold ferrous objects such as metal scraps, debris, or waste. This enables efficient and safe handling, sorting, and disposal of ferrous materials in applications such as construction, demolition, recycling, and waste management.