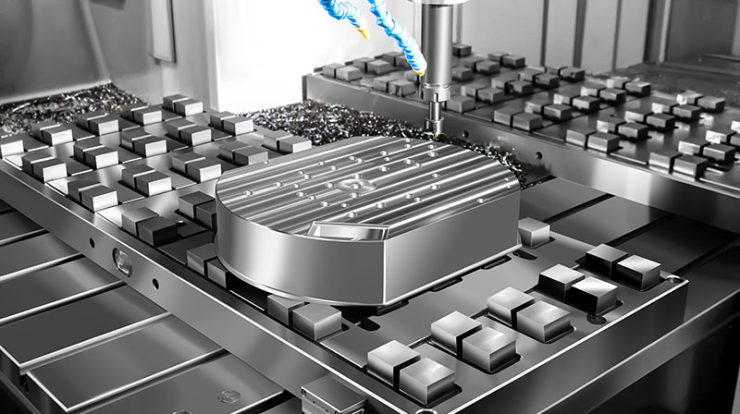

Electro Permanent Magnetic EOAT with Quick Change System

An EOAT (End-of-Arm Tooling) quick change system is a mechanism designed to swiftly and easily swap out different tools or grippers attached to the end of a robot arm. It allows for rapid tool changes without the need for manual adjustments or significant downtime. The EOAT quick change system typically includes a base mounting plate attached to the robot arm and a corresponding mounting interface on each tool or gripper. The tools or grippers can be quickly and securely attached or detached from the robot arm using this system. It enables efficient adaptation to different manufacturing processes or tasks. The EOAT quick change system enhances the versatility and productivity of robotic systems in various industries, such as manufacturing, assembly, and material handling.

Electro Permanent Magnetic EOAT, combined with an EOAT quick change system, offers several advantages in robotic applications.

Fast and Convenient Tool Changes

The EOAT quick change system allows for quick and easy tool or gripper swaps, eliminating the need for manual adjustments. When combined with EPM technology, the magnetic tool can be securely attached or detached from the robot arm in a matter of seconds, significantly reducing downtime during tool changes.

Versatility

EPM EOATs can accommodate a wide range of tools or grippers, thanks to their ability to generate strong magnetic forces. With the EOAT quick change system, different magnetic tools can be seamlessly interchanged. This enables the robot to tackle various tasks without extensive reprogramming or lengthy setup times.

Enhanced Safety

EPM EOATs provide a reliable and secure gripping force using magnetic technology. The magnets only consume power during the attachment or detachment process, ensuring that the grip remains stable even in the event of a power loss. This inherent safety feature reduces the risk of accidental tool release and provides a more secure working environment.

Increased Efficiency

The combination of EPM EOAT and the quick change system streamlines production processes. Rapid tool changes allow the robot to adapt to different workpieces or tasks, maximizing production throughput and efficiency. The ease of swapping tools also facilitates better utilization of the robotic system and optimizes overall workflow.

Reduced Cost

The ability to quickly switch between tools or grippers using the EOAT quick change system, coupled with the versatility of EPM technology, eliminates the need for multiple dedicated robots or extensive tooling setups. This reduces equipment costs and simplifies the automation setup, making it more cost-effective and flexible for various production requirements.

Overall, the combination of an EOAT quick change system and electro permanent magnetic EOATs empowers robots with enhanced versatility, efficiency, safety, and cost-effectiveness in a wide range of industrial applications.

For more information, please contact HVR MAG at export@hvrmagnet.com