6 Features of Magnetic Table for Milling Machine

In the actual production of milling operations, we should be skilled in the application of machine settings, work piece clamping, tool selection and many other aspects. The magnetic table for milling machine is a tool for clamping the work piece. It shortens the setting time and reduces the deformation rate of the work piece. It has the following features:

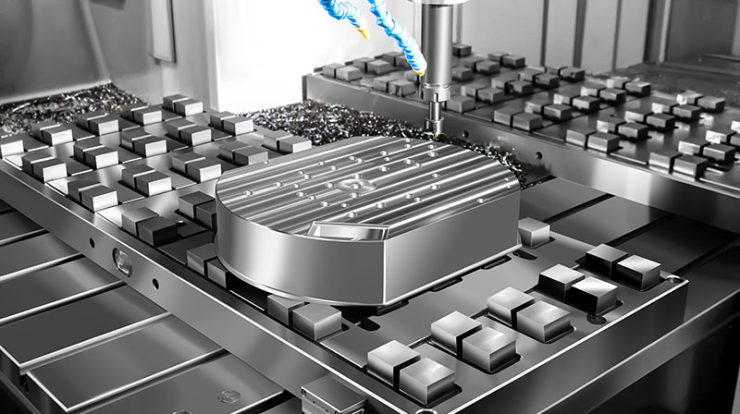

Uniform clamping

The magnetic table for milling machineis flat. That applies a uniform magnetic force to the underside of the work piece. And the magnetic table of HVR MAG has a magnetic force of up to 16 kg/cm² to ensure that the work piece is held firmly in place. If the underside of the work piece has a concave or convex surface, floating magnetic blocks can be fitted to match the shape of the work piece. When clamping work pieces with a large surface area, it minimises vibration and protects the machine spindle and cutting edge.

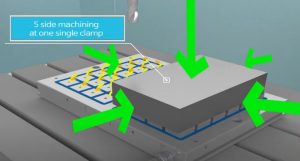

Five-sided machining

As the magnetic table for the milling machineonly absorb the underside of workpiece, there is no obstruction around the top and sides of the workpiece. This allows you to achieve five-sided machining and some more difficult machining methods. Better machining capabilities will undoubtedly increase the competitiveness of your business.

Non-destructive machining

The surface of our magnetic table for milling machine is finely ground, very flat and smooth, and will not wear the surface of the workpiece. Some customers are concerned that the magnetic force may affect chip removal or inserts. This is not a concern as our magnetic table surface has a permeability depth of 13-18mm. The height of the chip removal and the height of the inserts are well above this magnetic field range. So normally the magnetic table will not affect machining accuracy. However, if the work piece is particularly thin for special machining, there may be poor chip evacuation resulting in the tool striking.

Quick clamping

HVR magnetic table for milling machine use electrical permanent magnets. An electric current is used to switch the direction of the magnetic field of the internal permanent magnet material. A single magnetisation or demagnetisation takes only 1 second. This means that the workpiece is clamped or released in just 0.3-6 seconds. When using a magnetic table, the process of fixing your workpieces becomes very easy. Simply place the workpiece in the correct position and press the magnetisation switch. Once magnetisation is complete, the magnetic force of the permanent magnet material will not diminish even when the power cord is removed. So there is no need to worry about power consumption.

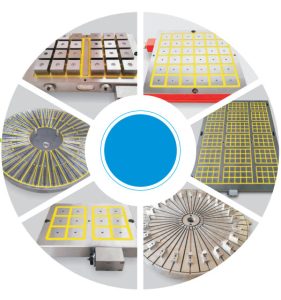

Universal clamping

Whatever the shape or size of the workpiece, it can be machined directly on the magnetic table. As long as it is made of magnetically conductive material. There is no need for an additional range of clamping tools.

Low maintain cost

The HVR magnetic table has an all-steel surface. It is resistant to corrosion, mechanical impact and does not generate heat. There are no internal moving parts, no wear parts, no maintenance. And the whole system is free from leakage and contamination.

With its unparalleled advantages, the electro-permanent magnetic chuck is widely used in the machine tool industry as a fixture for metal cutting (including turning, milling, grinding, planing, drilling, etc.). They are suitable for general machine tools as well as high precision CNC machines etc.

If you are looking for the right magnetic table for milling machine, please contact us for customisation. (export@hvrmagnet.com)