Magnetic Clamp for Welding: Enhancing Efficiency and Precision

Magnetic clamp for welding are innovative tools that have gained popularity in the welding industry. This blog aims to explore the effectiveness of magnetic clamps for welding and provide insights on what to consider when using them. From improved stability to enhanced productivity, magnetic clamps offer notable benefits in welding operations.

Do Magnetic Clamp Really Work? Yes, magnetic clampsfor welding are highly effective tools that simplify and optimize the welding process. They utilize strong magnetic fields to securely hold metal pieces together during welding, providing stability and precise alignment. When used correctly, magnetic clamps significantly enhance the efficiency and quality of welds.

What to Look for When Using Magnetic Clamp for Welding?

Magnetic Strength

One crucial aspect to consider when using magnetic clamp for welding is the magnetic strength. Different welding applications may require varying levels of magnetic force. Ensure that the clamps you choose have a magnetic strength suitable for the thickness and weight of the metal being welded. Strong magnets provide a secure hold, minimizing the risk of movement or misalignment during the welding process.

Adjustable Angles and Positions

Flexibility in adjusting angles and positions is another important factor to consider. Look for magnetic clamps that allow for easy adjustment, enabling precise alignment of the metal pieces. This flexibility ensures that the weld joint is accurately positioned, resulting in strong and reliable welds.

Heat Resistance

Welding involves high temperatures, and it is vital to choose magnetic clamps that are heat resistant. Look for clamps made from materials that can withstand the heat generated during welding without losing their magnetic properties or being damaged. Heat-resistant magnetic clamps ensure long-lasting performance and reliability.

Ease of Use

Consider the ease of use when selecting magnetic clamp for welding. Look for clamps that are easy to position, adjust, and release. Quick and hassle-free setup saves valuable time and improves overall workflow efficiency. Additionally, easy release mechanisms allow for efficient removal of the clamps once the welding is complete.

Size and Weight

The size and weight of the magnetic clamps should be appropriate for the welding application. Ensure that the clamps are compact enough to fit in tight spaces without obstructing the welding process. Lightweight clamps are easier to handle and maneuver, reducing operator fatigue and improving productivity.

Safety Precautions

Always follow safety precautions when using magnetic clamp for welding. Be aware of any potential hazards, such as the magnetic field interfering with nearby electronic equipment or the risk of objects being attracted to the magnets. Proper training and adherence to safety guidelines are essential to ensure a safe working environment.

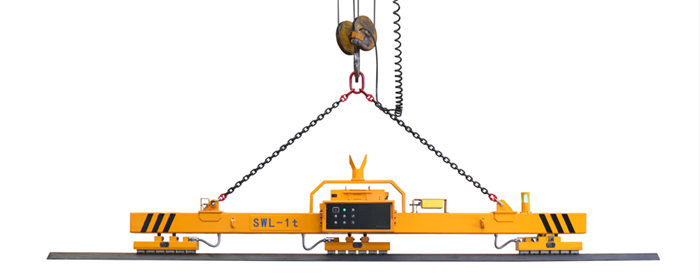

Features of HVR MAG‘s magnetic clamps for welding

HVR MAG’s magnetic clamp for welding meet all these requirements. The magnetic clamps made of electro-permanent magnets have a strong suction force and ensure that the workpiece is not displaced. Our electro-permanent magnets have a standard temperature resistance of 80°C and a maximum temperature resistance of 180°C. For higher working temperatures, they can be equipped with a water cooling system.

HVR MAG’s magnetic clamp for welding is easy to use. Its electrical control system can be connected to your intelligent welding system. Or controlled manually or remotely. It only uses electricity at the moment of clamping and releasing the workpiece (within 2 seconds). And the magnetism does not disappear during the welding process even in the event of an electrical failure. Making it energy efficient and safe. The compact size does not take up much of the working stroke.

Size/shape/holding force of HVR MAG’s magnetic clamp for welding can be custom manufactured in accordance with your specific application needs. Welcome to contact us.