Clark Forklift Operator and Site Safety Tips

Forklift tires for gravel

When was forklift invented

Clark Forklift Operator and Site Safety Tips

February 10, 2021

What are the CLARK operator and site safety tips?

- Know the common hazards around the site

- Ensure the operator is properly trained

- An operator should have a daily routine

- A site must be designed with safety in mind

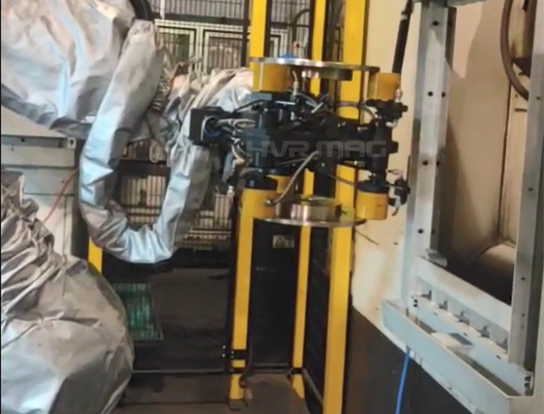

Aside from functionality and durability, CLARK forklifts are also designed with safety in mind. Features are included in the vehicles, with some notable examples such as the operator restraint systems, automatic parking brakes, speed control limits, and high-visibility orange seat belts. But apart from the machinery itself, the user and owner also have a part in keeping their selves and others safe. To help you, here are the CLARK forklift operator safety tips. Keep on reading!

Know The Common Hazards Around the Site

Before an operator can start using a forklift, he or she must first be informed about the common hazards around the site. This will give you an idea about the risks that are constantly present and steps you can do to prevent them. Listed below are some of the dangerous situations you should avoid:

- Falling objects due to unsecured loads

- Falling over because of excessive speeds and loads

- Collisions due to reduction of visibility

- Slipping due to wet and uneven floor conditions

- Accidents because of pedestrians and operators using the same paths

Fortunately, these accidents can be avoided if you follow the manual on operating your forklift. Inquire with your supplier about the speed control feature of your vehicle so you have an idea of how it works. Clark Forklifts are also made with increased visibility from all sides, with the option to add rearview cameras. But even if these features are present, an operator must always be responsible to avoid these problems.

Ensure The Operator Is Properly Trained

When looking for a forklift operator, only qualified and trained persons should be authorized. This is where licensure comes in. These are usually given by government institutions so you can get a professional certification. Written and practical exams are included in this, with a requirement to complete a minimum number of hours to pass.

This is important because safety at the job site starts with the operator himself. To avoid accidents, only properly trained persons must be hired to do this job. They know how to follow the rules when it comes to wearing the right personal protective equipment, and also the ins and outs of using the forklift. Operators are also retrained when new equipment is brought in or when they perform unsatisfactorily.

Some of the competencies that operators must qualify for are as follows:

- Workplace communication

- Professionalism

- Health and safety procedures

- Interpretation of technical drawings

- Tool and equipment maintenance

- Operation of the forklift

An Operator Should Have a Daily Routine

A trained operator will know his or her responsibilities when it comes to forklift and site safety. Some of the things that should be part of their daily routine before using the vehicle are as follows:

- Completing a daily visual checklist (tires, lights, manuals, forks, engine oil, radiator, breaks, etc.)

- Wearing of personal protective equipment

- 3-point contact system when mounting: Keep both hands and one foot gripped on the appropriate areas when getting on the forklift

- Buckling the seatbelt upon sitting

- Returning controls to neutral

- Disengaging the clutch on manual vehicles

- Applying brake on automatic vehicles

- Keeping hands and feet inside the cabin

After this, the operator must be careful in using the vehicle. It is important to maintain visibility and drive at a consistent speed at all times. Before going in a specific direction, you must always look for any pedestrians, especially when turning at corners. After operating, a post-op checklist must also be completed by inspecting the vehicle.

A Site Must Be Designed with Safety in Mind

Aside from the forklift itself, an operator must also keep an eye out around the site. A visual communication system can warn both pedestrians and drivers to be extra careful especially in certain areas. Traffic signs with speed limits can help avoid collisions inside or outside a warehouse. This can also help point to specific directions such as exits, loading docks, and inventories.

Aside from signs, floor marking systems will also help reduce risks. This is important especially at warehouses with multiple forklifts. These markings will help direct the flow of traffic, designate an area to park the heavy equipment, keep pedestrians on the walking zones, and alert operators for hazards ahead.

Aside from controlling traffic inside a site, marking tapes can also help segment a warehouse. This can save time when it comes to directions in a large facility, with operators being easily instructed to go to different color-coded areas. In low-light environments, glow in the dark tapes can also be used.

Key Takeaway

These Clark forklift operator safety tips will help reduce the risks when it comes to occupational hazards at the worksite. The key thing to remember is to have this heavy equipment used by certified individuals and design the working environment in a way to prioritize everyone’s protection.

If you require forklifts at your job site, you may send a message to Multico for assistance. As the leading brand of forklift all around the world, you can rely on Clark products for their functionality, durability, and safety features.