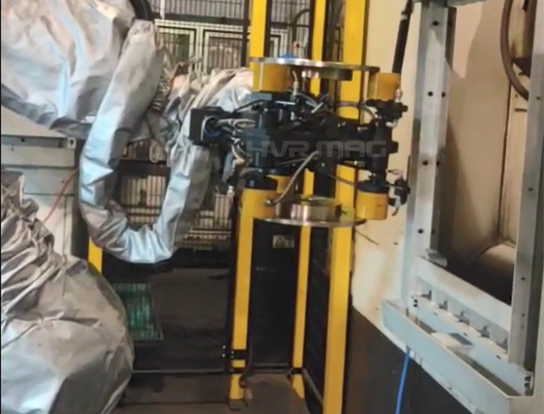

magnetic gripper for special environment

How is magnetic gripper for special environment? If you are a magnet user, perhaps you have encountered or heard of these special situations.

We all know sometimes it is tricky to find the right solution for some specific working conditions. That’s why we always do custom manufacture for our customers. Then here we will talk about the scenarios of magnetic gripper application: high temperature, high frequency, waterproof, and anti-corrosion environments.

High-temperature environment

The working temperature usually needs to be controlled below a certain temperature. The highest temperature HVR MAG’s magnetic gripper can endure is 650℃ by now, with the water-cooling system adopted. Exceeding this limited maximum temperature will cause the coil keel to deform or melt. Thus the circuit will have problems, making the magnet in a state of suspension. Excessive temperature will also affect the magnetism, or even cause permanent demagnetization.

High-frequency environment

The automation industry requires about 5-10 seconds for a single cycle, which is too high and we generally do not recommend such a design. We recommend using frequency control of 15 seconds or more. This is generally the same design for industrial robots, with the fastest single cycle of 15 seconds. This will allow enough time for the inside of the magnet to dissipate as much heat as possible. Generally, in high-frequency handling, we will increase the thickness of the coil, so that its instantaneous current is smaller, reducing the heat and increasing heat dissipation time.

Waterproof environment

HVR MAG has provided electro-permanent magnets with water-proof devices for outdoor lifting, magnetic gripper, injection mold change, and CNC chuck. Since in the rain, in the acid wash, cutting fluid, and other environments, we will use an all-steel type for the electro permanent magnet. The outlet box will also be well waterproof.

Anti-corrosion environment

When in acid washing, salt washing, and some other processes, the magnet material and production process will change mainly based on the corrosion strength of the solution. The magnet shell is not only all-steel but also has to choose the right type corresponding to the degree of corrosion resistance.

You are finding a magnetic gripper solution for your specific working environment or just some ordinary working conditions? Welcome to contact HVR MAG at: export@hvrmagnet.com. We have been manufacturing magnetic gripper for special environment, accumulating a lot of experience and cases (Click to know more!).