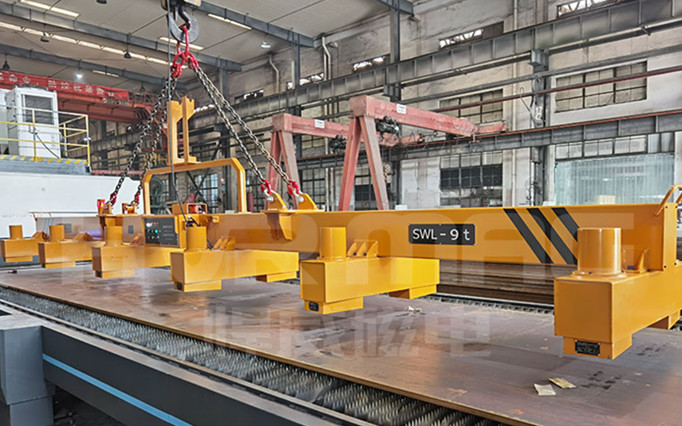

Cutting Table Magnets – Magnetic Sheet Metal Lifting System

What Are Cutting Table Magnets?

Cutting table magnets, just as the name implies, are lifting magnets that are used for the loading & unloading of steel plate or sheet metal onto or off the cutting line table. They’re usually magnetic lifting system, which utilizes the magnetic clamping force to pick up and position the metal parts.

Uses of Magnetic Lifting System for Cutting Table:

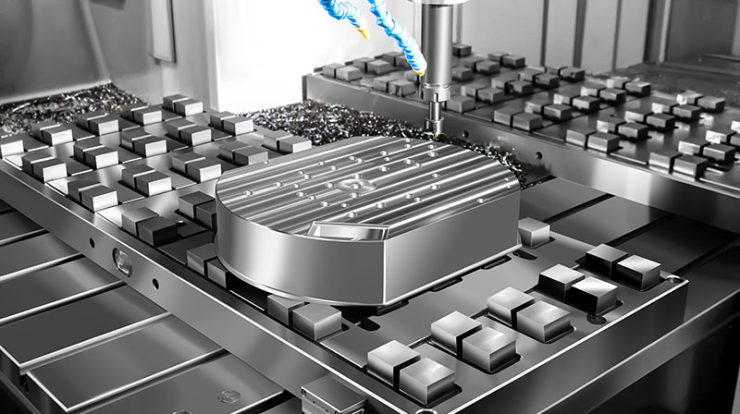

- Special material handling needs required in precision flame, plasma, laser, water jetcutting table operations.

- Loading plate and then after cutting, unload cut parts and skeleton in one step.

- Parts can also be separated from the skeleton to improve the sorting process.

Plate Handling Types for Cutting Table

A: for both loading & unloading of sheet and cut parts

B: for just loading of a single whole steel plate

Unlike mechanical lifting devices like clamps and slings, cutting table magnets allows you to clear cut parts, unload skeletons and reload with new plates quickly, efficiently, and safely. This magnetic sheet metal lifting system eliminates costly idle machine time, which translates into increased production.

Magnetic Sheet Metal Lifter Manufacturer

As an industrial lifting magnets manufacturer, HVR MAG can tailor design and produce cutting table magnets meet the special material handling needs required in precision flame, plasma and laser cutting table operations.

HVR MAG’s magnetic lifting system, consisted of electro permanent magnets and lifting beam, is equipped with a radio remote control for the worker to operate away from the cutting table. If you have any question or need help for loading & unloading a cutting table, please feel free to contact us.