Material Handling Equipment Safety Guide for Clark Forklifts

Hand truck forklift

Other names for forklift

Material Handling Equipment Safety Guide for Clark Forklifts

August 10, 2021

What is the material handling equipment safety guide for Clark forklifts?

- Consider where your forklift is used

- Determine the load capacity you need

- Prioritize comfort for safety purposes

- Take advantage of the safety features

- Keep up with the maintenance

- Make use of attachments for extra safety

When it comes to operating material handling equipment, there are certain safety protocols that you need to follow. Operators must complete pre and post-operation checks, wear the appropriate high-visibility clothing and be aware of the hazards in the environment. Lastly, it is vital to choose the right brand of forklift. To know more, keep on reading for the material handling equipment safety guide for Clark forklifts!

Consider Where Your Forklift Is Used

Depending on where you will use your forklift, you might need to choose among different types to ensure the safety of your workers. For outdoor applications, internal combustion forklifts such as the Clark L series are suitable because of their industrial diesel engine. They can provide longer run times and higher torque compared to other fuel counterparts.

But if you’re looking for material handling equipment for indoor use, Clark also has battery-operated reach trucks and counterbalance forklifts such as the Clark EPXi. These produce zero to little emissions so they’re perfect for clean environments too!

Determine The Load Capacity You Need

Another thing you need to consider when renting or purchasing a forklift is the load limit of the truck. This is vital because you can only carry loads that are within the rated capacity of your material handling equipment to ensure the safety of your operator and other people in your workplace. Be mindful of the center of gravity as you operate the forklift on-ramps, uneven floors, and corners.

Fortunately, Clark provides a range of options when it comes to loading capacity. For example, the S series has a capacity of 2000 to 3200 kilograms. This can help lessen the need for multiple trips when moving goods from vans to the warehouse.

Prioritize Comfort for Safety Purposes

Comfort is an important factor in ensuring the safety of your operator. It helps reduce fatigue and makes a forklift less physically demanding to drive. For example, the Clark L series offers a spacious driver’s compartment that has plenty of headroom and legroom. Instead of constantly having to mind the space above and below, the driver can just focus on their task—which is to keep their eyes on the path ahead!

Aside from that, the interface is also user-friendly, so it doesn’t require any complicated thinking. All the components are easy to reach, including the ergonomic steering wheel, so fatigue is reduced.

Take Advantage of the Safety Features

Operating material handling equipment in construction sites, warehouses, and logistics facilities can be risky. If your operator is not properly trained, they can get hurt due to overloading or turnovers.

All Clark forklifts are made with built-to-last engineering and safety features to give operators and business owners peace of mind. When combined with proper training, it can help prevent accidents and injuries. All their forklifts are designed with wide visibility so an operator can be aware of the obstacles in the area while working.

One of the safety features available on the Clark S-series is the wet disc brake, which improves the stopping power of the forklift. It also comes with a speed reduction feature to regulate driving. If you have your eyes on the Electric EPXi series, you can take advantage of the “Operator Presence System” sensor which prevents the forklift from moving unless an operator is seated.

Keep Up with The Maintenance

Forklift maintenance has a big impact on the safety of your workers. Without preventive inspections and repairs, your material handling equipment could suddenly malfunction in the middle of the operation. Fortunately, Clark’s forklifts are simple and easy to maintain. This way, you don’t have to stress about the expenses. Aside from ensuring safety, this can also help reduce downtime, which can be costly!

For example, the diesel XinChai engine on the Clark L series is widely used internationally. That means that there are plenty of mechanics who know how to maintain and repair it. You don’t need to use fancy computer diagnostic equipment when inspecting it too!

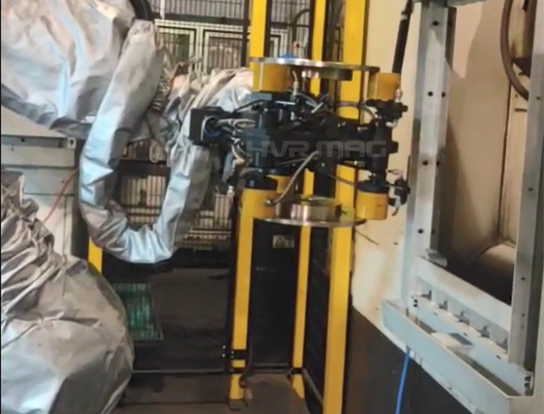

Make Use of Attachments for Extra Safety

Clark forklifts have optional equipment and accessories that can help operators stay safe and efficient in your worksite. Depending on the model, you might be able to opt for additional strobe lights and rear work lights which might be useful in a workplace with narrow pathways and low visibility. Other features include SE Tires, non-marking tires, various seat options, additional hydraulic functions, and more!

With additional accessories available, you can focus on the specific safety needs in your workplace.

Key Takeaway

With this material handling equipment safety guide for Clark forklifts, you can take advantage of the features of your equipment to ensure the well-being of your operators and employees. It also improves productivity, which is important for all types of businesses.

If you’re interested in renting or purchasing Clark forklifts, you can send a message here! Multico is Asia’s leading equipment specialist and supplier of high-quality material handling equipment in the Philippines.