Unearthing the Past: A Comprehensive History of the Excavator

Keywords:hydraulic scrap magnet, mini excavator buckets, excavator rock bucket

In the world of heavy equipment, few pieces of equipment are as widely used as excavators. But despite their ubiquitous presence on construction sites and earthmoving operations, it may come as a surprise to learn that the roots of the excavator trace back several centuries. Indeed, its history is one that spans the globe and encompasses a wide variety of technological innovations, from the ancient times to the cutting-edge hydraulics of today’s machines. In this article, we’ll take a closer look at the fascinating story of the excavator, exploring its many iterations and shedding light on its pivotal role in the evolution of civil engineering, construction and mining

What is an Excavator?

An excavator, also known as a digger, is a large construction equipment used to dig, move and manipulate various types of earth, rocks, and debris. Typically, an excavator features a long arm that extends out from a rotating cab, which can pivot in a full circle. The arm often has several hydraulic-powered cylinders that allow operators to adjust its length, angle, and depth to remove materials from the ground or reach high places. Excavators often have crawlers (tracks) or wheels that move them around the work site and are used in construction, mining, road building, and other heavy-duty applications. They often come in various sizes, with smaller ones weighing under a ton to the largest excavators weighing over 100 tons. Due to their versatility, efficiency, and power, excavators have become an essential piece of equipment in many construction and industrial operations. If you would like to know more about the excavator, we suggest you read our article here.

Short Brief on the History of the Excavators

Excavators, in some form or the other, have been around since ancient times, with evidence of animal and manual digging tools dating back to the Bronze Age. However, it wasn’t until the 1800s that steam-powered excavators were introduced, revolutionizing the industry. The first commercial hydraulic excavator was introduced in the 1950s, using pressurized fluid to power the machine for increased efficiency and maneuverability. In the 1990s, computer technology was integrated into excavators, allowing for more precise and automated movements. Today, excavators come in a variety of sizes and models, from mini excavators for small construction projects, to massive machines used in mining and other industrial applications. The constant advancements in technology continue to improve the functionality and capabilities of these important machines.

Early Days of Excavators

Excavation has been an essential activity for human beings for thousands of years, starting with the use of primitive tools. Historians have found evidence of the use of simple machines and tools to excavate and move earth in ancient civilizations, such as the ancient Greeks, Romans, Egyptians and Indians. The early days involve crude implements like shovels, pickaxes, and wheelbarrows that were used for excavation. For example, 5000 years ago, the Egyptians used wooden shovels and baskets to move soil during the construction of the pyramids. There are also evidences of excavation equipment run with animal power like horses and oxen.

First excavator invented by William Otis

The first known mechanical excavator was invented in 1835 by American inventor William Otis. This machine was called the “Otis Excavator” or the “Steam shovel” and was used to dig the Boston and Albany Railroad tunnels and also the New York city water tunnels. This rail carriage mounted equipment was powered by steam. It was able to move up to 16 cubic yards (12 cubic meters) of dirt per hour.

This steam machine featured a long arm with a bucket attached to the end that could be used to scoop up earth or rocks. The arm was attached to a rotating platform that allowed the excavator to reach a wide range of angles. This engineered design revolutionized excavation and construction, making it possible to dig deeper and wider tunnels and foundations in a fraction of the time it would have taken with manual labor. Today, modern excavators are still based on the basic principles used in this invention of the 19th century.

Newer versions of the Steam Shovel

Steam-powered excavators became more common in the late 1800s and early 1900s. However, newer versions after the first invention did not have a lot of technological advancements. They continued to be heavy, slow and difficult to manage, and operators had trouble controlling them. These early models also had trouble with the distribution of steam and sometimes suffered boiler explosions. Despite these difficulties, the development of steam-powered machines marched forward.

The introduction of the continuous extractor steam shovel in late 1800s marked a significant milestone in the development of the modern steam shovel. The design featured a cable supported rotating wheel with buckets around its periphery, allowing for greater mobility and range. These machines were used in major construction projects, such as the Panama Canal and the Trans-Siberian Railway. They were also used in the mining industry to extract minerals from the ground.

Introduction of Internal Combustion engines

Steam shovels were slow and cumbersome, requiring large amounts of water and coal to function. In the late 1800s, there was a new revolution in the automobile powertrain – the invention of the internal combustion (IC) engines. Rudolf Diesel invented the Diesel engine in 1893 and the Gasoline engine (called the Otto engine) was invented in 1876 by Niclaus Otto. Both these IC engines brought breakthrough transformation in the automobile industry. The heavy equipment industry was also quick to catch up with these promising technologies.

The new generation of excavators with internal combustion engines were introduced in the 1900s, and revolutionized the construction and mining industries. Relying on internal combustion engines allowed them to be used in more remote locations, deep mines and distant construction sites. Also, these machines were faster, more efficient, and easier to operate than their steam-powered counterparts. They dramatically reduced the amount of water and coal needed, making them more sustainable and cost-effective.

The first gasoline-powered excavators were developed by companies like Koehring and Bucyrus-Erie, and quickly became popular among contractors and mining companies by mid-20th century. With their increased mobility and power, IC engine-powered excavators played a major role in the rapid expansion of infrastructure projects around the world.

Introduction of hydraulic power

Hydraulic power in its present form was patented by Joseph Bramah in 1795 as a “Hydrostatic machine”, which was an earlier form of a hydraulic press. The Hydrostatic machine was built on the principles that Blaise Pascal established in the mid-1600s. Sir William George Armstrong perfected some of the hydraulic designs leading to his inventions like the hydraulic accumulator, in England, where it was used in construction of the Hull docks.

Unlike today’s excavators that use hydraulic fluid, water was used to operate the hydraulic functions. Also, it was not a true hydraulic machine, but a hybrid that used cables to operate the bucket but with a hydraulic cylinder operating a set of multiplying sheaves. The idea was not successful, neither on this machine nor on a machine of somewhat similar design built by the unrelated Frank F. Armstrong for Penn Iron Mining Company in the United States in 1914.

In the 1950s, the introduction of hydraulic power allowed excavators to operate more efficiently and with greater precision. Hydraulic system uses hydraulic fluid under pressure to move the equipment, which is much more efficient and powerful. This system is superior because it allows operators to control multiple functions (levers & controls) at the same time, which enhances productivity. Advanced hydraulic pumps have allowed for the development of new excavator designs that meet different requirements such as the ability to operate in harsh environments. As a result, the utilization of excavators has become widespread in the construction and excavation industry due to their high efficiency and reliability.

Introduction of the Crawler in excavators

The introduction of crawler technology in excavators has been a significant part of technological progress in the construction industry. Crawler excavators, also known as caterpillar excavators, have replaced wheeled excavators in most construction sites due to their adaptability and versatility. They are designed with a special track system that enables them to maneuver through rough terrain, climb steep inclines and work on soft ground without getting stuck. This advancement in excavator design has significantly impacted the construction industry, allowing for more efficient and productive work. The use of crawlers has also resulted in changes in excavator design, with manufacturers focusing more on building machines with a lower center of gravity and optimized hydraulic systems. These improvements not only increase machine stability, speed and productivity but also ensure operator safety in challenging work conditions.

Excavator Attachments and more versatility

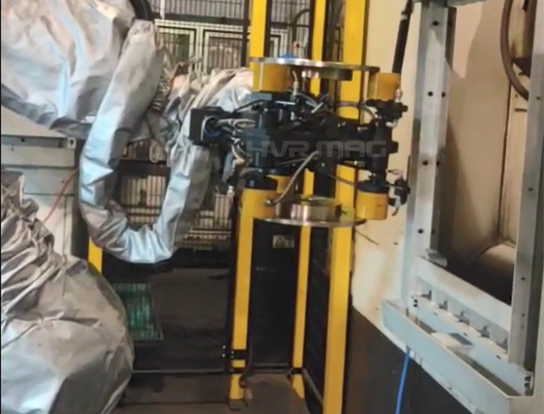

With the advent of hydraulic power and innovations in hydraulic motors, newer types of excavator attachments were invented. The gradual addition of trenchers, mulchers, grapples and many other attachments led to excavators becoming extremely versatile. If you would like to know more about the different excavator attachments, we recommend you read our article on excavator attachments here.

Newer versions of the excavators were also popping up in the mid-20th century. The first backhoe loader was introduced in the 1950s, combining the capabilities of a bulldozer and a hydraulic excavator. The backhoe loader is now one of the highest sold construction equipment worldwide.

Range of different excavator sizes

With more innovations in manufacturing technology, excavator manufacturers started making excavators in different sizes. In the 1970s, mini-excavators were introduced, which were smaller and more maneuverable than large excavators. These machines were ideal for work in tight spaces and indoor construction projects. Advances in compact excavator design have continued to this day, with manufacturers introducing models with increasing power and efficiency. Now, we have excavators in the size of small cars to the size of large buildings. Modern excavators’ operating weight ranges from less than a ton to more than a thousand tons.

Conclusion

From manual labor to the steam-powered machines of the past, and on to the powerful and efficient hydraulic excavators and the advanced technologies of today, the excavator has come a long way in its history. Excavators have revolutionized the construction and mining industries and have made it possible to undertake projects on a scale never before possible. As technology continues to advance, it is likely that the excavator will continue to evolve and become even more versatile and powerful.