The Role of Electro Permanent Magnetic Grippers in the Automotive Industry

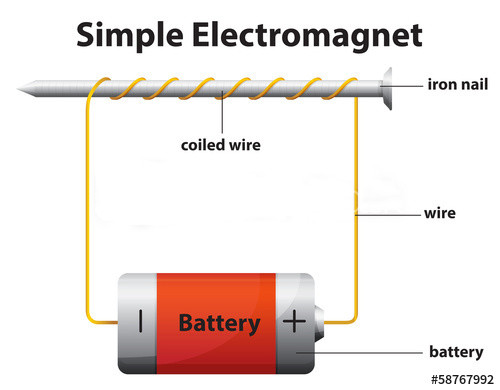

In the fast-paced automotive industry, efficient and safe handling of heavy loads is of utmost importance. This is where electro permanent magnetic grippers have emerged as a game-changer. Combining the power of electromagnets with the convenience of permanent magnets, these innovative devices have revolutionized material handling processes in automotive manufacturing plants.

Enhanced Productivity

Electro permanent magnetic grippers offer the automotive industry enhanced productivity like never before. These magnets utilize the concept of electro permanent magnetism, ensuring that once the magnet is activated with an electric current, it retains its lifting power even if the electricity supply is cut off. This means that automotive manufacturers can lift and transport heavy loads quickly and efficiently, without the need for a continuous power supply. The result? A significant boost in productivity and operational efficiency.

Improved Safety of Electro Permanent Magnetic Grippers

Safety is a top priority in any industry, particularly in the automotive manufacturing sector. Electro permanent magnetic grippers have made significant contributions to improving workplace safety by minimizing the risk of accidents during material handling processes. These magnets are designed with advanced safety features such as fail-safe mechanisms, ensuring that loads remain securely attached even during power fluctuations or failure. Additionally, the ability to lift heavy loads with precision and control reduces the chances of human error or strain-related injuries, further enhancing safety standards.

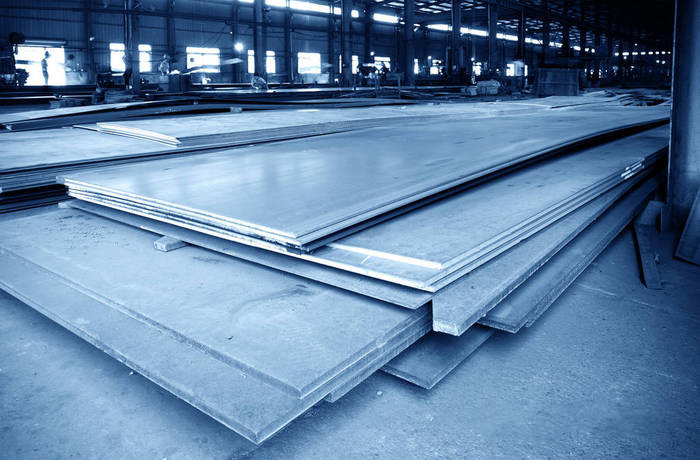

Versatility in Handling Various Materials of Electro Permanent Magnetic Gripper

The automotive industry deals with a wide range of materials, including heavy parts, components, and assemblies. These magnets excel in handling these diverse materials due to their versatility. Whether it’s handling steel plates, engine blocks, or chassis components, these magnets can easily adapt to different shapes and sizes, making them highly efficient in various automotive manufacturing processes. Their customizable and modular designs allow for easy integration into existing production lines, adding flexibility and adaptability to the manufacturing process.

Optimized Workflow

Efficiency and a streamlined workflow are crucial in the automotive industry, where every second counts. They contribute significantly to optimizing the workflow within manufacturing plants. These magnets expedite the loading and unloading processes, eliminating time-consuming manual labor and reducing production downtime. By minimizing the need for multiple handling equipment or manual interventions, these magnets enable manufacturers to achieve faster turnaround times, resulting in increased production capacity and improved delivery schedules.

Environmentally Friendly of Electro Permanent Magnetic Grippers

As sustainability becomes an intrinsic part of industries worldwide, the automotive sector is no exception. Electro permanent magnetic grippers contribute to the industry’s eco-conscious efforts by reducing energy consumption in material handling processes. By utilizing the power of permanent magnets once activated, these magnets reduce the need for continuous power supply, resulting in lower energy consumption and decreased carbon footprint. This eco-friendly aspect aligns well with the automotive industry’s efforts to adopt greener practices.

Conclusion

Electro permanent magnetic grippers have become an indispensable tool in the automotive industry, revolutionizing material handling processes. From enhanced productivity and improved safety to greater versatility and optimized workflows, these magnets offer a range of benefits. As the automotive industry continues to evolve, the role of electro permanent magnetic grippers will only grow in significance, enabling manufacturers to meet increasing demands efficiently and sustainably. For more information, please contact HVR MAG at export@hvrmagnet.com