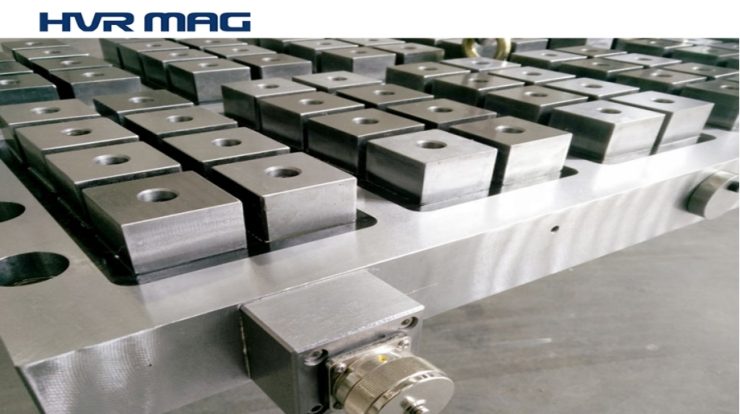

Magnetic Chuck for Milling Machine

Milling machines are used to remove material from a workpiece to create a desired shape or surface finish. Workholding devices are essential in milling operations to secure the workpiece in place during machining. Magnetic chuck for milling machine is one of the most common workholding devices used in milling machines.

A magnetic chuck is a type of workholding device that uses magnetic forces to hold a workpiece in place during milling operations. It is a rectangular or circular plate made of magnetic materials, such as neodymium iron boron or samarium cobalt, that is mounted on the milling machine’s table.

Why Use a Magnetic Chuck on Milling Machine?

Magnetic chucks offer several advantages over traditional workholding devices, such as vises or clamps. First and foremost, magnetic chucks provide a strong holding force that can securely hold a workpiece in place. This is particularly useful when working with heavy or irregularly shaped workpieces that are difficult to hold with traditional workholding devices.

Magnetic chucks are also easy to operate, making them an ideal choice for both novice and experienced machinists. They require minimal setup time and can be quickly mounted on the milling machine’s table. Additionally, magnetic chucks can be used for a wide range of milling operations, including drilling, tapping, and reaming.

Features of Magnetic Chuck for Milling Machine

Strong holding power: Magnetic chucks can provide strong holding power, which makes them ideal for holding heavy or irregularly shaped workpieces.

Easy to operate: Magnetic chucks are easy to operate, making them an ideal choice for both novice and experienced machinists.

Versatile: Magnetic chucks can be used for a wide range of milling operations, including drilling, tapping, and reaming.

Precise positioning: Magnetic chucks can hold workpieces in precise positions, which is essential for achieving accurate milling results.

Advantages of Magnetic Chuck for Milling Machine

Increased productivity: Magnetic chucks can increase productivity by reducing the setup time required for workholding. This allows machinists to spend more time on milling operations, which can increase throughput.

Improved safety: Magnetic chucks can improve safety by reducing the risk of accidents that can occur during manual workholding.

Reduced distortion: Magnetic chucks can reduce distortion in workpieces, which can improve milling accuracy.

Cost-effective: Magnetic chucks are a cost-effective workholding solution, as they require no additional clamping devices or fixtures.

Conclusion

Magnetic chucks for milling machines are an effective workholding solution that provides strong holding power, precise positioning, and increased productivity. Machinists can benefit from the ease of use and versatility of magnetic chucks, as well as the improved safety and cost-effectiveness they offer. If you are looking for a reliable and efficient workholding solution for your milling operations, a magnetic chuck is definitely worth considering.

HVR MAG offers the safest and most energy efficient electro-permanent magnetic chuck for milling machine. Electricity is only used at the moment of clamping and releasing the workpiece, so no electrical failure can affect the machining result. The magnetic strength can be adjusted to suit a wide range of workpiece sizes and shapes. We guarantee a quality product and service for our customers. Feel free to contact us.