Lifting Magnet for Structural Fabrication? Yes!

As the title says, lifting magnet for structural fabrication. Yes! It ‘s true that more and more structural fabricators abandon the traditional lifting devices and embrace lifting magnet? You can probably figure it out after understanding the working principle of the electro-permanent lifting magnet.

Because although the traditional lifting devices has a low initial investment cost, the lifting speed is low, the labor cost is high, and lifting accidents occur frequently every year, with great security risks. The upgraded electro-permanent lifting magnet product can solve the above problems, with high efficiency, energy-saving, safety, and other characteristics.

Today let the electro-permanent lifting magnet manufacturer HVR MAG introduce its working principle in detail so that you know more about it.

And electro permanent lifting magnet can solve the above problems, with high efficiency, energy-saving, safety, and other characteristics, this electromagnetic suction cup spreader manufacturer to introduce its working principle in detail, so that we know more about it.

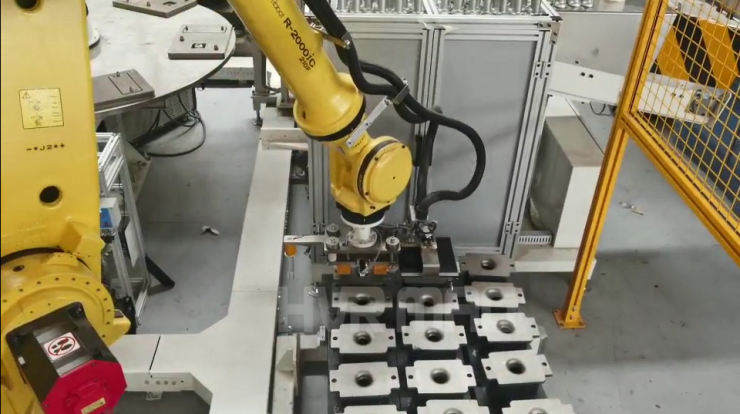

The scene of lifting steel plates with HVR MAG’s electro permanent lifting magnet

Electro-permanent lifter magnet adopts electro-permanent magnet technology to realize the control of the product, through the electric control system to control and convert the distribution of its internal magnetic circuit, so that the permanent magnetic field is balanced within the system itself, and is externally characterized as a demagnetized and relaxed state (i.e. non-absorbing state); or released to the working magnetic pole surface of the electric permanent magnet, and is externally characterized as magnetized and clamped state (i.e. absorbing state), which only consumes electric energy at the moment of magnetization and demagnetization, without electricity consumption during the work, saving more than 95% of electric energy and greatly controlling the working cost.

Electro permanent lifter magnet equipment composition: with the electronically controlled permanent magnet system as the core, the whole set of electro-permanent lifter magnets consists of an electric permanent magnet, lifting chain, cable, electro-permanent magnet controller, and other accessories.

Electro permanent lifter magnets can be widely used by changing the shape design for:

- Iron plate, steel plate, and other plate handling and laser cutting machine feeding.

- Lifting and handling of various steel profiles.

- Handling and feeding of iron coils, steel coils, and other coils.

- Iron pipe, steel pipe, and other pipe handling and loading.

- Forging prefabricated parts handling and feeding.

- Other kinds of magnetic materials with a flat surface and regular shape.

The era of industrial intelligence has come, electro permanent lifter magnets will also be used in more and more places. Understanding its working principle can let us better to choose the right lifting equipment, avoiding blind choice. HVR MAG can provide customized design and production according to the structural fabricator’s working conditions.

Interested in lifting magnet for structural fabrication? You are welcome to contact us at: export@hvrmagnet.com