Magnetic grippers for automatic handling of car absorbers

The car absorber is a perishable accessory in using the car. The good or bad work of the car absorber will directly affect the smoothness of the car driving and the life of other machine parts. How do we improve absorber production efficiency and quality? HVR magnetic grippers will tell you the answer.

What is a car absorber?

A car absorber is used to suppress the shock and impact from the road when the spring rebounds after absorbing the shock. It is widely used in cars to accelerate the attenuation of frame and body vibrations to improve the smoothness of the car’s ride. When passing over uneven roads, although the shock-absorbing springs filter the vibrations from the street, the springs still have a reciprocating motion. The shock absorber is used to suppress this spring jump.

The life expectancy of a car absorber is approximately six years. Most air suspension products are used in luxury cars for millions of dollars, and replacing a set of these products may require a replacement cost of 50,000 to 60,000, so how can the price of the products be controlled through product structure optimization and manufacturing cost control?

How do we improve the quality of automotive absorbers?

A good absorber must have excellent damping and recovery force and excellent sealing performance to achieve the best damping and bring a good driving comfort experience. What determines this superb quality is the material and production process of the shock absorber. Each shock absorber is manufactured through a strict standard production process, going through a complete series of operations from production and processing to testing, then to tuning and testing, etc. So how can we improve handling efficiency and increase shock absorber production?

Which company will boost your absorber production?

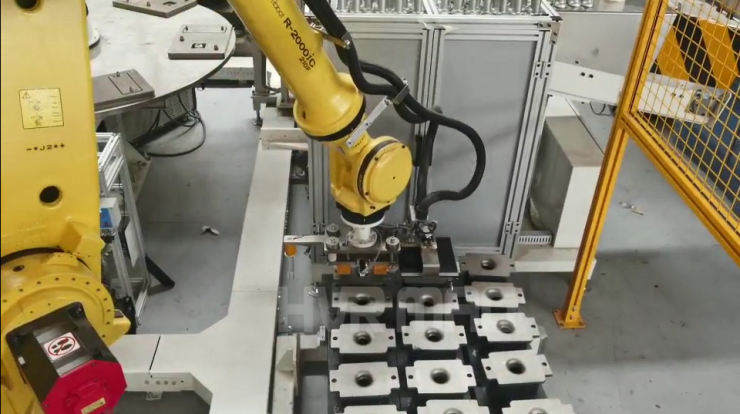

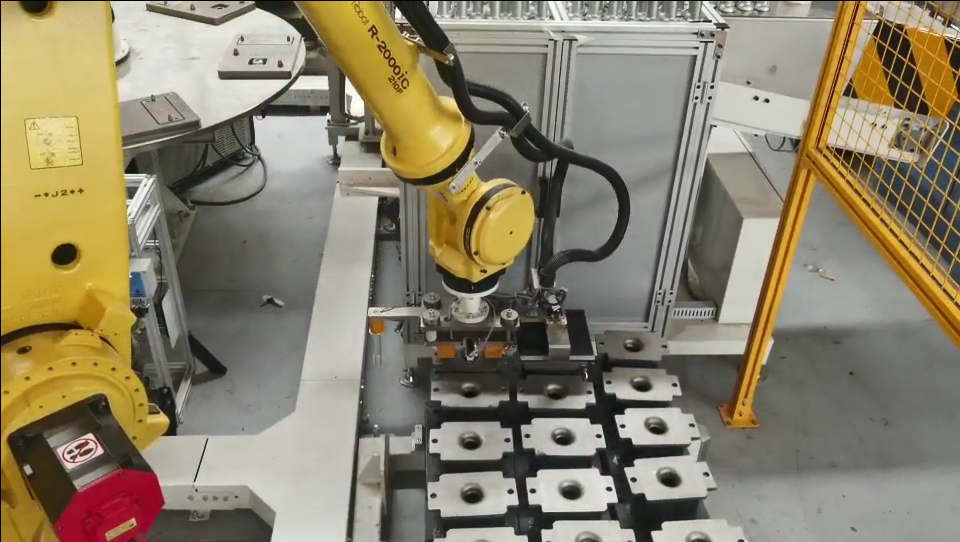

The answer will not shock you. HVR offers magnetic grippers that will boost your productivity and reduce the changeover time. Our magnetic grippers have the proper systems to prevent interruptions when encountering power failure. The robots with magnetic grippers definitely will reduce the labor cost and decrease the product damage. From design to use, our team of experts will take care of the heavy lifting, so you don’t have to. Contact us today to get started.