Lifting Magnet for Cutting Table: Automation Solution

What is Lifting Magnet

Lifting magnets are widely used in material handling as automation solutions. They are designed to lift and transport ferromagnetic materials such as steel plates, beams, and other heavy components. A lifting magnet offers advantages like increased productivity, improved safety, and reduced labor costs in industries such as manufacturing, construction, and logistics.

What is Cutting Table

When it comes to cutting steel plates, a cutting table refers to a heavy-duty table or machine specifically designed for this purpose. These tables are commonly used in industries such as metal fabrication, construction, and manufacturing.

A steel plate cutting table typically consists of a solid, flat surface made of materials like steel or cast iron. The surface often has a grid pattern or markings to assist with measurements and alignment. The table is constructed to withstand the weight and force applied during the cutting process, and it is usually equipped with clamps or fixtures to secure the steel plate in place.

Various cutting methods can be employed on a cutting table for steel plates, including plasma cutting, laser cutting, and oxy-fuel cutting. These cutting techniques utilize specialized equipment and tools to precisely cut through the steel material.

Overall, a cutting table for steel plates provides a stable and reliable work surface for efficient and accurate cutting operations in the metalworking industry.

Why Choose Electro Permanent Lifting Magnet for Cutting Table

An electro permanent lifting magnet is a highly efficient and cost-effective solution for loading plates onto cutting tables. It is a popular choice among manufacturers for its ability to securely lift and manipulate heavy steel plates.

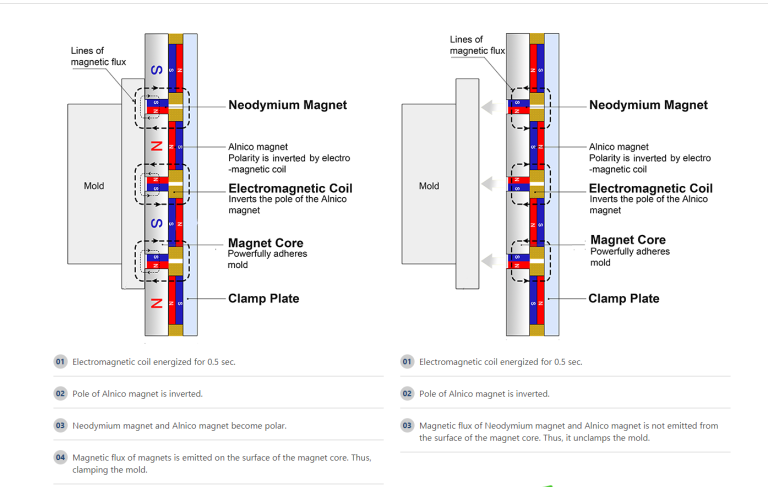

Electro permanent lifting magnets combine the benefits of both electromagnets and permanent magnets. They utilize an electrical current to activate the magnet, allowing it to securely grip the steel plate. Once the magnet is energized, it can lift and transport the plate to the cutting table with ease. This eliminates the need for manual labor and improves overall operational efficiency.

Furthermore, an electro permanent lifting magnet can also unload cut parts while keeping the remaining skeleton or scrap material intact. This feature is beneficial for optimizing material usage and minimizing waste during the cutting process.

Additionally, an electro permanent lifting magnet is a great match for a gantry robot in the context of a cutting table application. This magnet is typically lightweight and compact, making it suitable for integration with the gantry robot’s end-effector or tooling, which allows for efficient and flexible handling of steel plates, adapting to the robot’s movement and positioning requirements.

Conclusion

Overall, using an electro permanent lifting magnet provides a reliable and productive method for loading plates onto cutting tables and efficiently manipulating heavy steel materials in the manufacturing industry.

HVR MAG offers lifting solutions consistent with your demand. For more information and customization, please contact us at export@hvrmagnet.com