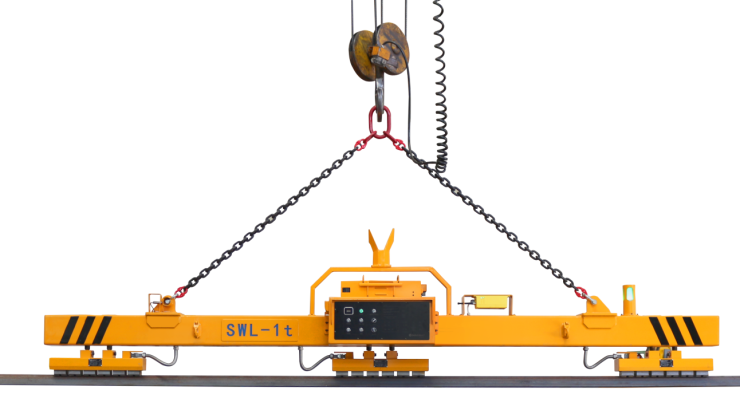

In-depth Analysis of HVR MAG’s Lifting Magnets for Steel Plate

There are many different types of lifting magnets for steel plate in the market, which makes steel manufacturers difficult to choose a right one. Here, HVR MAG will do an in-depth analysis of our newly delivered industry heavy duty lifting magnets, to help them gain a better understanding of plate handling operation. The designed total … Read more