In-depth Analysis of HVR MAG’s Lifting Magnets for Steel Plate

There are many different types of lifting magnets for steel plate in the market, which makes steel manufacturers difficult to choose a right one. Here, HVR MAG will do an in-depth analysis of our newly delivered industry heavy duty lifting magnets, to help them gain a better understanding of plate handling operation.

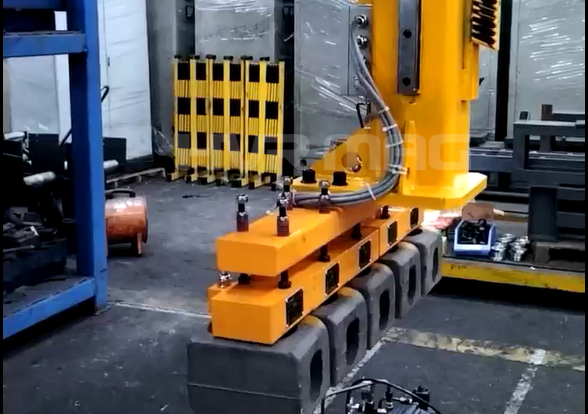

The designed total lifting capacity of this magnetic lifting device is 25 ton. It utilizes 2 different models of magnet lifters to do the lifting job.

There are 4pcs of HEPMP-5000P50 magnets, and 2pcs of HEPMP-3000P50 magnets, distributed on each side of the spreader beam.

Dimensions of steel plates to be handled: 8-150mmX6-12mX1.8-2.5m

Plate handling process includes picking up a single plate from the truck, and stacking it in a designated position.

Previously, workers in this shop floor were using plate clamps to move the plates, which were often scratched by the clamps. And the frame of plates tended to curl when being lifted up, let alone the hidden safety hazard in the handling process.

What makes them go for our lifting magnets for steel plate? Below is why:

1. Offer flexible lifting solutions for 8-150mm plates, and selective control of magnet lifters for lifting plates with various lengths.

2. Precise lifting of single plate without picking up the second sheet, which ensures the plates to be stacked in serial order(each plate is marked with a unique number), as the plates are to be loaded to be cut in order.

3. Magnetic lifting causes no damage to plate surface, which exerts no effect on the processing of next procedure.

4. No dropping of suspended plate due to a sudden power failure, as the magnetic lifting force remains.

5. Less energy consumption, as no power consumed in lifting state. They only need electricity for MAG and DEMAG phase, to clamp on or release the plate.

6. The remote requires only one worker to operate, reducing labor intensity & risks for personnel

Some may wonder, how do our lifting magnets for steel plate, ensure that they can pick up one plate every time for plates with different width?

Well, this is a good question. For each set of our magnetic lifting device, the magnetic force can be adjusted to realize the precise handling of one single plate each time with varying width.

Using electromagnetic lifting magnets for steel plate, can bring you other benefits like faster handling speed with handling cost reduction, better use of the storage areas by increasing available space, etc. That’s how we help companies like a manufacturer or wholesalers of steel sheets, by bring performance and safety to their workplace.

What is your experience with steel sheets storage? You can share us the problems you met in material handling by geting in touch with us. We’re glad to help you and provide customized lifting magnets for steel plate handling.