Electrically Switched Permanent Magnetic Chuck

The permanent magnetic chuck is mainly used for clamping medium-heavy grinding or milling workpieces. It is a common tool in machine shops, mould shops, forging shops, steel mills, shipyards and other steel-using places, and can greatly improve the clamping efficiency of magnetically guided workpieces. However, if you want a workpieace holder that can precisely adjust the magnetic strength, an electronically controlled permanent magnetic chuck would be a better choice.

The electrically switched type of permanent magnetic chuck has following features :

- High-performance permanent magnetic material NdFeB is used as the core of the product, making it smaller in size but stronger in suction force.

- The safety factor of the electronically controlled permanent magnetic chuck is 3.5 times the rated suction force.

- The optimised magnetic circuit design of the magnetic chuck makes the residual magnetism almost zero.

- The professional design of the magnetic chuck can realize zoned clamping, and the magnetic force range and magnetic strength can be precisely controlled.

- It is energised only when the workpiece needs to be fixed or released. It therefore saves energy and does not generate heat.

In practical machining, cutting, drilling, milling, turning and grinding operations, electro-permanent magnetic chucks can give you these benefits:

High precision

The flat table surface provides a uniform gripping force for controlled machining accuracy. The workpiece is not deformed by uneven forces. We also offer magnetic accessories to suit shaped workpieces.

High efficiency

With electrically switched type of permanent magnetic chuck, your workpiece holding time is significantly reduced compared to conventional mechanical clamping. This helps you to increase your machining efficiency.

Versatile

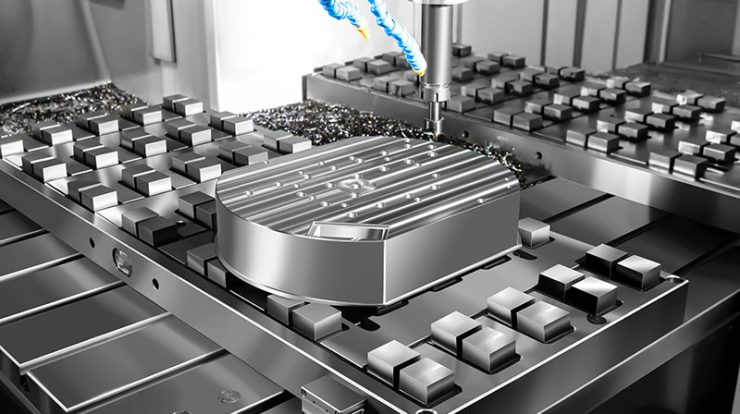

The permanent magnetic chuck only attaches to one side of the workpiece and there are no parts to block the perimeter of the workpiece. This means you can achieve 5-sided machining or even more difficult workpiece cuts. With a magnetic chuck, any size and shape of workpiece can be securely clamped. Except of special workpieces that are particularly thin.

HVR MAG is a specialist manufacturer of magnetic chuck. If you require customised workholding solution, please feel free to contact us at:export@hvrmagnet.com