Remote Controlled Lifting Magnet – Types and Differences

As the technology advances, and the popularization of smart manufacturing, remote controlled lifting magnet has been widely used in steel material handling process to increase efficiency and boost productivity. Here, we will go through several different types of lift magnets and their differences.

Let’s start with the most commonly used magnet lifter – permanent lifting magnet. This manually switched on and off lifting equipment, has no remote.

Remote controlled lifting magnet includes electromagnetic lifting magnets and electro-permanent lifting magnets. Their main difference lies in the working principle.

The electromagnetic type, works on constant supply of electricity.

While the electro permanent magnetic type, only needs electricity to switch the magnetic force on and off. There’s no power consumption in working.

Remote Controlled Lifting Magnet – Different Types HVR MAG Offers

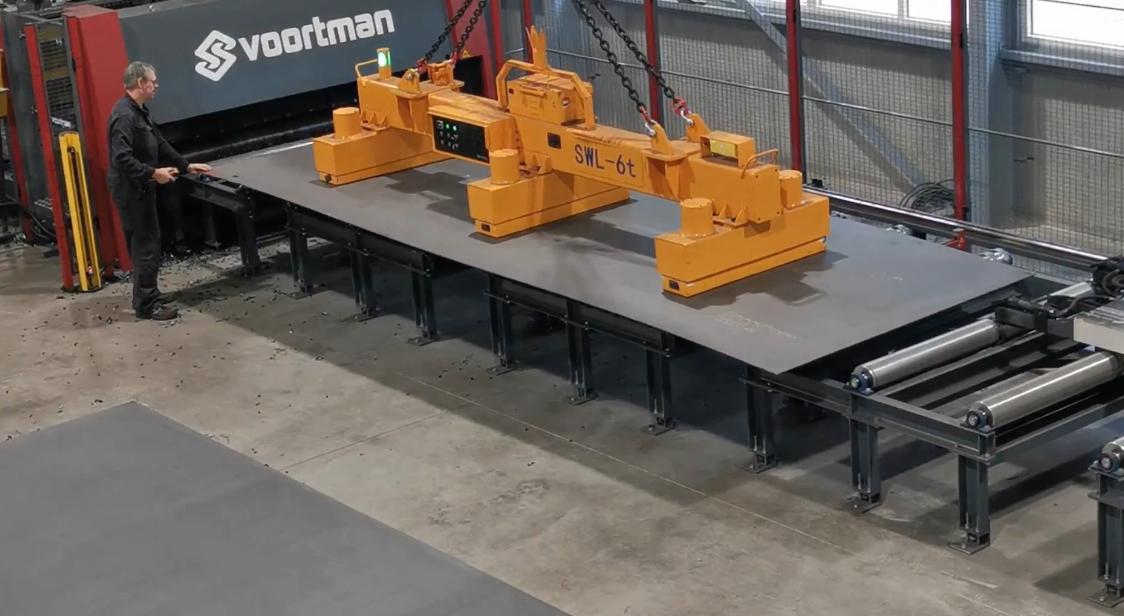

Magnetic Spreader Lifting Beam: based on the same electro permanent magnetic technology, we offer magnetic lifting systems that has power cable, shown in the following picture,

or with independent battery supply to use in areas or places where power supply is unavailable.

Magnet Lifter

electrically switched permanent lifting magnet

battery operated electrically switched permanent magnet lifter, remote controlled

How to select the right magnetic lifting equipment for your purpose?

Depending on the specification of the materials to be handled, the overall working conditions in your shop floor, and other special requirement like high temperature, sophisticated manufacturing procedure, etc.

Contact our professional sales team to make the right decision for your steel material lifting purpose.