End of Arm Tooling Grippers

end of arm tooling grippers

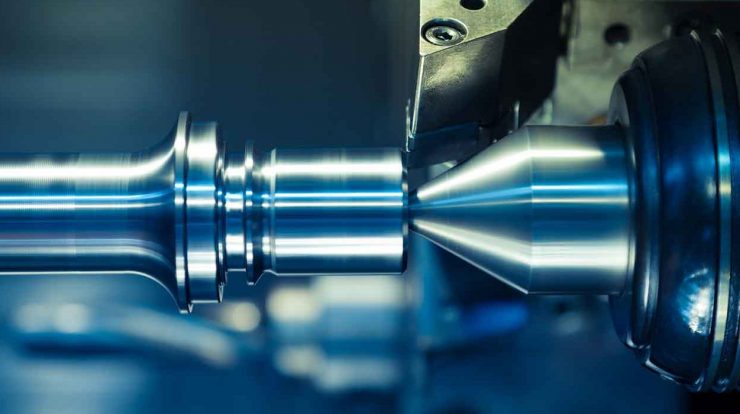

End of arm tooling grippers are an essential component of robotic systems and automated processes. They are used to grip and hold objects securely during the manufacturing process. There are several types of end of arm tooling grippers available, each with its own strengths and weaknesses. In this blog, we will discuss the differences between types of end of arm tooling grippers and whether magnetic grippers are suitable for steel parts handling.

Types of End of Arm Tooling Gripper

Pneumatic Grippers:

Pneumatic grippers use compressed air to open and close the gripper jaws. They are fast and lightweight, making them ideal for high-speed applications. Pneumatic grippers are also durable and can handle heavy loads.

Electric Grippers:

Electric grippers use a motor to open and close the gripper jaws. They offer better control and precision than pneumatic grippers, making them suitable for delicate or precise applications. Electric grippers are also more energy-efficient than pneumatic grippers.

Hydraulic Grippers:

Hydraulic grippers use hydraulic fluid to open and close the gripper jaws. They are best suited for heavy-duty applications and can handle large loads. Hydraulic grippers are also durable and can withstand harsh environments.

Vacuum Grippers:

Vacuum grippers use suction to hold objects in place. They are ideal for handling objects with smooth or flat surfaces.

Magnetic Grippers:

Magnetic grippers use a magnetic field to hold objects in place. They are ideal for handling objects made of ferromagnetic materials such as steel.

Differences Between Types of End of Arm Tooling Grippers

The main differences between types of end of arm tooling grippers are their method of operation, speed, precision, and suitability for different types of applications. Pneumatic grippers are fast and durable, making them ideal for high-speed applications, while electric grippers offer better precision and control. Hydraulic grippers are best suited for heavy-duty applications, while vacuum grippers are ideal for handling objects with smooth or flat surfaces.

Magnetic grippers are the best choice for handling ferrous materials. Magnetic grippers can be adapted to steel workpieces of all shapes and sizes. When gripping thin or very smooth steel parts, the adsorption gripping method causes no deformation or wear.HVR MAG’s magnetic grippers are made of electric permanent magnets and consume only 5% of the power of electromagnets. You don’t have to worry about high power consumption or safety issues.

In short, choosing the right type of end-of-arm tool gripper is important to ensure safe gripping and prevent damage to parts during the manufacturing process. The differences between types of end-of-arm tool gripper include their method of operation, speed, accuracy and suitability for different types of applications. While magnetic grippers are suitable for handling steel parts, they cannot handle non-ferromagnetic materials. However, if you need to handle large quantities of steel, our electro-permanent magnetic grippers are the best choice.

Related question

hydraulic magnet for excavator

What is hydraulic magnet for excavator?

A hydraulic magnet for an excavator is a specialized attachment that uses hydraulic power to lift and transport ferrous materials. It consists of a magnet mounted on the end of an excavator arm or boom.

The hydraulic magnet is designed to attract and hold ferrous objects, such as metal scraps, debris, or waste, making it easier and more efficient to clear construction sites, recycling facilities, or demolition areas. The magnet can be activated and deactivated using hydraulic controls, allowing the operator to selectively pick up and release materials as needed.

This attachment offers several advantages, including increased productivity, reduced labor, and improved safety by eliminating the need for manual handling of heavy or sharp objects.

Hydraulic magnets for excavators are commonly used in industries such as construction, demolition, recycling, and waste management, where the efficient collection and disposal of ferrous materials are essential.

excavator grapple bucket

Types of excavator grapple bucket

There are several types of excavator grapple buckets available, each designed for specific applications and material handling tasks. Here are some common types:

- Fixed Thumb Grapple Bucket: This type of grapple bucket features a fixed thumb attachment that provides a solid grip for handling materials such as logs, rocks, and debris.

- Hydraulic Rotating Grapple Bucket: These grapple buckets have a hydraulic system that allows the grapple to rotate, providing enhanced flexibility and maneuverability when picking up and placing materials.

- Demolition Grapple Bucket: Designed for heavy-duty applications, demolition grapple buckets feature sturdy construction and reinforced tines for handling large and rugged materials, such as concrete and demolition debris.

- Rake Grapple Bucket: Rake grapple buckets combine the functionalities of a grapple and a rake. They are effective for tasks like land clearing, brush removal, and sorting materials.