Where is Electro Permanent Lifting Magnet A Better Choice

Keywords: electro permanent magnet, hydraulic scrap magnet, excavator ditching bucket

Electro permanent magnet

There are types of lifting magnet to handle heavy duty made of ferromagnetic materials, one of which is electro permanent magnet. In this article we will compare different types of lifting magnet and discuss what industry can take full advantages of it.

hydraulic scrap magnet/excavator scrap magnets

Common Types of Lifting Magnet

Permanent lifting magnet: This magnetic field enables the magnet to securely lift and hold heavy objects without the need for a continuous power supply.

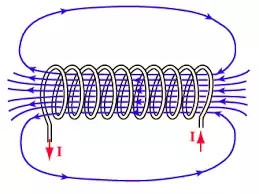

Electromagnetic lifter: It requires a continuous supply of electric current to create and maintain the magnetic field. The lifting capacity of an electromagnetic lifter can be easily adjusted by controlling the strength of the electric current flowing through the electromagnet.

Electro permanent lifting magnet: It consists of a magnetized core like a permanent magnet, but this magnet can be activated or deactivated by an electric current, just like an electromagnet. Once activated, it can hold and lift ferromagnetic objects without the need for a continuous power supply, making it energy efficient and safe.

hydraulic magnet for excavator

In These Areas Electro Permanent Lifting Magnet Is A Better Choice

Thin steel sheet moving: Electromagnetic lifter creates deep magnetic field that can penetrate several steel sheets. This might be dangerous because sometimes it attract excess sheets. Electro permanent magnet can precisely lift single or multiple steel sheets based on instruction.

Shipping port material transporting: Steel handling at shipping port requires the lifter not relying on continuous power supply to avoid risks. Electro permanent magnet, in need of power only during activation and deactivation, can keep operating during power failure.

Wind tower monopile manufacture: Monopile manufacture involves long heavy steel plate processing. Electromagnetic lifter and electro permanent lifting magnet are commonly used to handle heavy objects. However, electromagnet requires power doing operation while electro permanent magnet not, which makes the latter on more energy saving. According to statistics, electro permanent lifting magnet saves 95% electricity compared to electromagnet lifter.

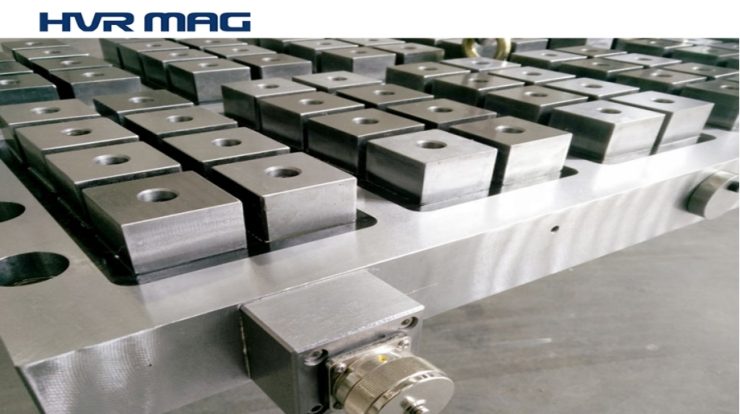

Intelligent manufacture: Intelligent gantry crane is usually used to lift steel plates of different lengths and thickness. In a set of electro permanent lifting magnet, each magnet can be controlled separately. This allows the electro permanent magnets to be controlled in groups, so it is able to lift hundreds types of workpieces of disparate sizes.

Steel plate cutting: Steel plate moving and cut parts picking are essential parts in steel processing. The magnetic force of permanent magnet can’t be adjust, so it is not compatible with all sizes of steel plates. In contrast, electro permanent magnet can adapt to various sizes of steel plates according to processing needs.

Recommendation from Lifting Expert

HY MAG is a magnet supplier, offering magnetic lifting solution for all industries. Undoubtedly, electro permanent magnet has transformed material handling practices across numerous industries. By combining the best features of permanent magnets and electromagnets, electro permanent lifting magnets enable faster, safer, and more efficient lifting and handling operations. To strive for increased productivity and competitiveness, electro permanent lifting magnet is a good choice to enhanced operational efficiencies and cost savings.

People Also Ask

What is magnet for trackhoe?

A magnet for a trackhoe, also known as an excavator, is a specialized attachment that utilizes a magnetic field to lift and handle ferrous materials. Designed to be mounted on the trackhoe’s boom or arm, the magnet provides efficient material handling solutions for industries such as construction, recycling, and scrap metal. Activated through hydraulic controls, the trackhoe magnet attracts and securely grips ferrous materials like steel plates, pipes, and scrap metal, simplifying sorting, clearing, and transportation tasks on the job site. This attachment enhances productivity and streamlines operations by facilitating the efficient handling of ferrous materials with the trackhoe.

Hydraulic Breaker Hammer

What are the common types of excavator attachment?

The common types of excavator attachments include buckets (such as digging, ditching, and rock buckets), hydraulic thumbs, grapples, rippers, augers, hydraulic hammers, and tilt buckets. Other popular attachments include demolition shears, compactors, and tree shears. Each attachment serves a specific purpose, such as digging, lifting, breaking, or grabbing materials. Some attachments are also designed for specialized tasks like landscaping, forestry, or demolition. Excavator attachments can greatly increase the versatility and functionality of the machine for various construction and earthmoving projects.