How Often Should You Replace Your Excavator Bucket Attachments?

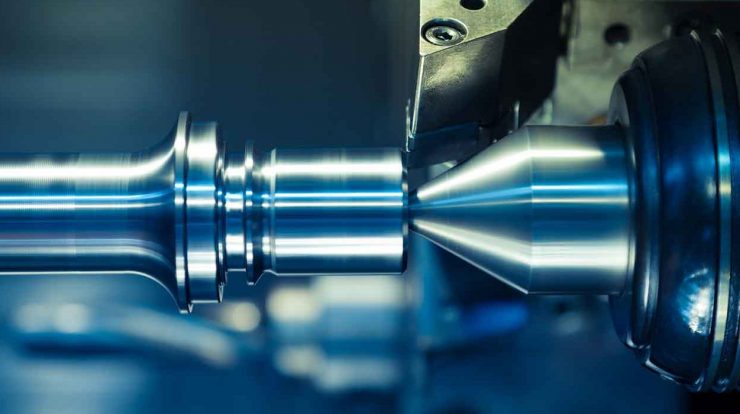

Excavator bucket attachments

As an essential piece of equipment for construction, landscaping, and site preparation work, excavators rely on their various attachments to handle a wide range of tasks. One of the most frequently used – and often overlooked – attachments is the excavator bucket.

Excavator bucket attachments is one of the most important places for excavators and the application frequency is very high. It can be said that buckets are indispensable for excavators. Without a bucket, the excavator cannot work normally. Due to the high frequency of application. , So the bucket wears out quickly, should the bucket be replaced frequently? How often should the excavator bucket attachments be replaced?

Just like any heavily-used tool, excavator buckets are subject to significant wear and tear over time. So how do you know when it’s time to replace this critical attachment?

The Lifespan of Excavator Buckets

The actual lifespan of an excavator bucket can vary quite a bit depending on several key factors:

- Usage Intensity – Buckets on excavators that see heavy, constant use will wear out much faster than those used more intermittently.

- Bucket Material & Design – Buckets made with higher-grade, abrasion-resistant steel tend to last longer than standard steel buckets.

- Bucket Size – Larger buckets used on bigger excavators experience greater stresses and wear.

- Jobsite Conditions – Digging in rocky, abrasive soils accelerates bucket wear compared to softer, sandy soil.

As a general guideline, most excavator buckets will need to be replaced every 1,000 to 2,000 hours of use, depending on the above factors. Some high-quality, well-maintained buckets may last up to 3,000 hours.

Signs It’s Time for a Bucket Replacement

There are several telltale signs that indicate your excavator’s bucket is nearing the end of its useful life:

- Excessive Bucket Teeth Wear – When the bucket teeth are worn down significantly, it reduces digging efficiency and can damage the bucket itself.

- Cracking or Deformation – Visible cracks, bends, or other structural damage to the bucket frame and sides.

- Reduced Bucket Capacity – As the bucket walls wear thin, the bucket’s volumetric capacity is diminished.

- Excessive Bucket Play – Too much play/movement in the bucket’s pivot points and linkages.

Replacing Excavator Buckets

When the time comes to replace your excavator’s bucket, it’s important to choose the right new bucket for the job and your specific machine model. Consulting with the excavator or attachment manufacturer can help ensure you get the optimal bucket configuration.

Keeping a close eye on your excavator’s bucket condition and replacing it proactively can help maintain productivity, avoid costly downtime, and ensure safe, efficient operation on the jobsite.