The definition and applications of magnetic chuck

Keywords: chuck definition, mini excavator auger attachment, magnet for excavator

chuck definition

Do you know magnetic chuck, and do you know its application? Read on if you are interested in it.

What is an electro-permanent magnetic chuck?

An electro-permanent magnetic chuck relies on permanent magnets to generate magnetic force and uses an excitation coil to adjust the strength, acting as a suction switch.

Advantages: high precision, no thermal deformation, energy saving.

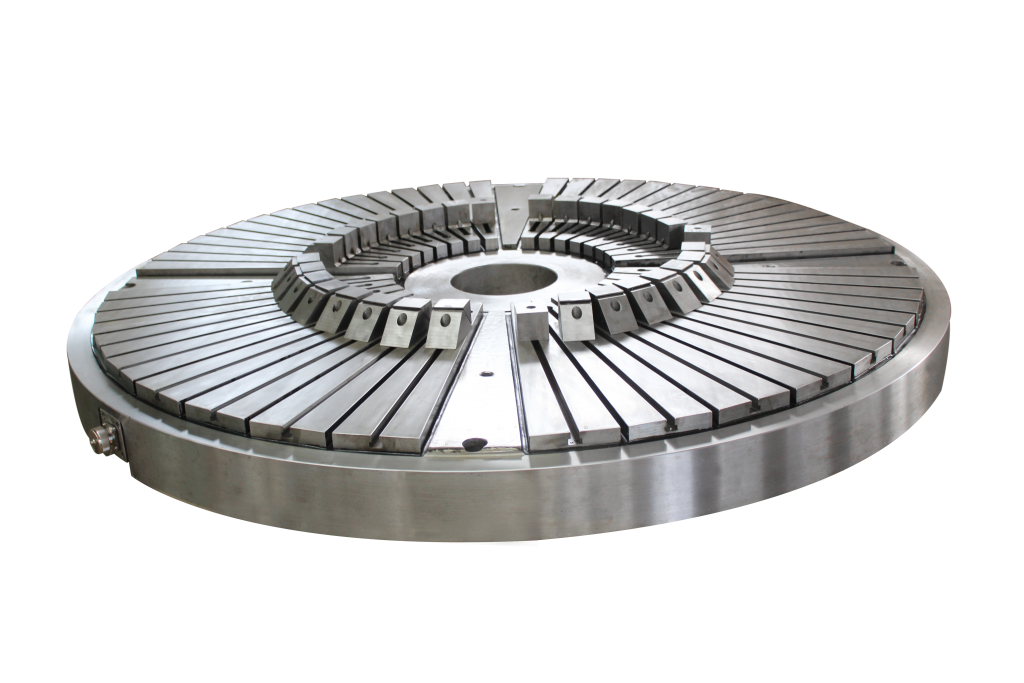

Classification: There are three main magnetic chucks: standard rectangular electric permanent magnetic chucks, powerful rectangular electro-permanent magnetic chucks, and round electro-permanent magnetic chucks.

Application areas of electro-permanent magnetic chuck:

- For CNC machine tools and machining centers

- For machining guide rails

- For lathe disc-shaped parts

- For the handling of large steel plates and the feeding of cutting machines

- For gripping machinery in the automotive industry and various automatic production lines

- Mould closing machines

Main applications:

- Metal cutting processing, quick mold change (injection molding machine, ceramic dry press), magnetic lifting.

- Metal cutting, including turning, milling, grinding, planing, drilling, etc., is suitable for both general machine tool applications and machining center applications without changing the original structure of the machine tool.

- Quick mold change, including injection molding machines, ceramic dry presses, etc., eliminating the need for many adjustments and making mold changes extremely fast. The profit margin for injection molding machines with electro-permanent magnetic chuck has increased steeply and is favored by users.

- Lifting and handling: For the lifting of a single steel plate, especially in the field of automobile axles, automobile chassis, container shipbuilding, etc., it is required that the steel plate be lifted and placed flat and that the single steel plate be lifted without sticking. The characteristics of the electro-permanent magnetic lifting system are precisely suitable for the above conditions.

- Welding clamping: All pipes and steel plates need clamping devices to tighten their positioning before being welded. The EPM clamps are superior to others in terms of their strong suction force, reliability, and ease of use.

magnet for excavator

A hydraulic magnet for excavator is a specialized attachment that utilizes hydraulic power to activate a magnet. It is designed to lift and handle ferrous materials, such as steel plates or scrap metal, during material handling operations. The attachment is mounted on the excavator’s boom or arm, and the hydraulic system controls the magnet’s activation and deactivation, allowing for efficient and convenient manipulation of ferrous objects. Hydraulic magnets enhance productivity and ease in industries like construction, recycling, and metal fabrication.

How about other attachment for excavator?

mini excavator auger attachment

A mini excavator auger attachment is a compact tool specifically designed for mini excavators. It is used for drilling holes in the ground for tasks like fence post installation and tree planting. The attachment consists of a hydraulic motor, a drilling bit or auger, and a mounting system for attachment to the excavator’s boom or arm. The hydraulic motor provides the necessary power and torque to rotate the auger, allowing for efficient and precise drilling operations. Mini excavator auger attachments offer increased productivity, accuracy, and reduced manual labor in small-scale excavation and construction projects.