robots with magnetic grippers for cnc machine

Robots with magnetic grippers are used to replace manual loading and unloading of workpieces on CNC machine tools, mainly for large batches, repetitive or heavy workpieces, and in harsh conditions such as high temperature and dusty working environments. It is characterized by accurate positioning, stable product quality, reduced machine tool and tool losses, adjustable working tempo, smooth and reliable operation, and easy maintenance.

In machining, many are currently using manual or special machines for loading and unloading, which is very suitable in the case of a single product and low capacity. Still, with the progress and development of society, the use of manual or special machines for loading and unloading has revealed many shortcomings and weaknesses.

Firstly, the structure of the machine is complicated and inconvenient to maintain, which is not conducive to the production of automated assembly lines;

Second, it does not have the characteristics of flexible processing, is challenging to adapt to product changes, and is not conducive to the adjustment of product structure;

Third, the manual labor is too high, easy to cause work accidents and low efficiency. With manual loading and unloading, product quality stability is not enough to meet the needs of high-volume, high-quality production.

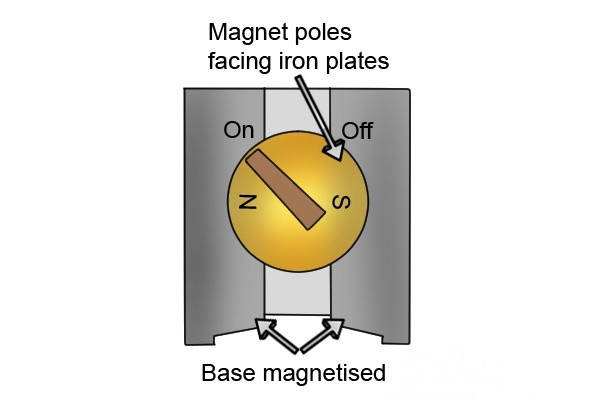

Loading and unloading robot systems equipped with magnetic grippers can avoid the above problems. It has high efficiency and product quality stability. A simple structure is easier to maintain and can meet the production of different types of products. The user only needs to make limited adjustments, and you can quickly adjust the product structure and expand production capacity, significantly reducing the labor intensity of industrial workers.

The robotic system mainly consists of industrial robots, silo system, end clamping system, control system, safety protection system, etc., as well as the client matching CNC machine tools composed of the automation system, through system integration, can realize single machine tools, processing units, assembly line and flexible processing units of machining automation. CNC machine loading and unloading robots have the advantages of high speed, high flexibility, high efficiency, high precision, no pollution, etc. They are a very mature machining aid and essential to developing a flexible manufacturing system FMS and a flexible manufacturing cell FMC. The CNC lathes and robots constitute a flexible manufacturing system and a flexible manufacturing cell, which can save colossal workpiece conveying devices. Simple structure and adaptability.

The combination of machine tool loading and unloading robots and CNC machine tools enables automatic workpiece gripping, loading, unloading, card loading, workpiece shifting and turning, and workpiece sequencing and processing, which can significantly save labor costs and improve production efficiency. It is particularly suitable for processing large quantities and small parts, such as bearing bushings (seats), motor end caps, increased turbines, commutators, brake discs, automotive gearbox gears, metal stamping structures, etc.

Robots with magnetic grippers can significantly improve the efficiency of loading and unloading, and we aim to accelerate your automation speed. contact us now to get started.

if you are interested in it, please visit our youtube for more videos: (5 Axis CNC machine working process for aerospace with magnetic gripper)