Magnetic grippers in the disc brake system

At present, semi-finished disc brakes are machined by hand by placing them on lathes, drilling machines, and grinding machines. They need turning, drilling, and grinding. After the process is complete, workers will remove the finished products by hand. To improve time utilization, product quality, and labor safety, how can we improve the efficiency of our disc brake production line?

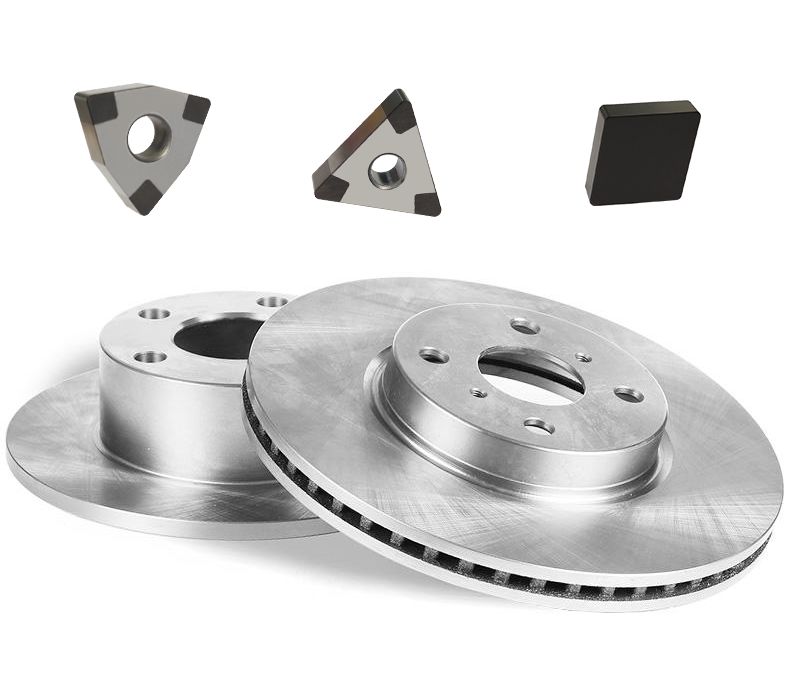

- What is a disc brake?

A disc brake is simply a round disc. It uses the calipers to squeeze pairs of pads against a disc or a rotor to create friction. This action slows the rotation of a shaft, such as a vehicle axle, either to reduce its rotational speed or to hold it stationary.

- The current condition of the disc brake production line

Workers have to work in a harsh, dusty environment. Due to the high speed of turning, punching, and grinding machines, manual picking and placing parts is tedious and labor-intensive. The control of time by personnel is unstable. The time utilization rate is low. And manual placing of components can lead to misuse. Other phenomena, the positioning of workpieces is not guaranteed as it should be, and the manual approach to the machine is prone to safety hazards such as clamping.

- How can we improve the efficiency of the disc brake production line?

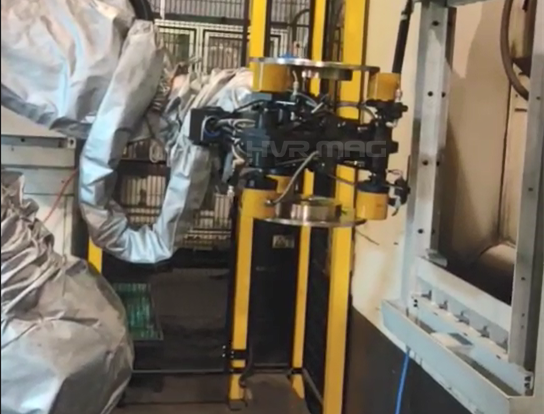

With the development of industrial technology, our customers use robots. HVR designs robotic manipulators according to the needs of our customers to achieve automatic loading and unloading of disc brakes. As a result, the use of magnetic grippers reduces the pressure on workers, improves efficiency, and promotes the development of factory production automation.

The robots with magnetic grippers can achieve 24-hour uninterrupted production, substantially improving production efficiency and equipment utilization. In terms of quality, the automatic operation of robots increases product quality stability. And it also reduces the safety hazards of the processing line and the hassle of manual management. At the same time, it not only dramatically shortens the processing time but also increases the production volume of disc brakes, and saves manpower to the greatest extent.

Never hesitate to contact us, we will provide you with the best plan!