Magnetic Grippers: Automatic Material Handling Solution in Special Vehicle Manufacture

Steel is a popular material choice for special vehicle components due to its strength, durability, and ability to withstand harsh environments. However, steel materials can also be heavy, bulky, and difficult to manipulate, which requires specific handling techniques and equipment. Automatic steel material handling can be an effective way to increase the efficiency of special vehicle manufacture. Magnetic grippers can be a useful tool in automatic material handling in special vehicle manufacture.

Difficulties of Material Handling in Special Vehicle Manufacture

Heavy Material Handling: Steel materials used in vehicles are often heavy and cumbersome, which makes their handling more challenging. Moving and lifting large steel sheets or heavy steel components require specialized equipment and strong workforce.

Safety Risks: Steel materials can pose safety risks during handling. The sharp edges and heavy weight of steel materials increase the chances of injuries if proper safety precautions are not followed. Manufacturers need to ensure that their workforce is trained in proper handling techniques and equipped with appropriate safety gear.

Welding and Fabrication: Steel materials often require welding and fabrication processes during

vehicle manufacturing. Ensuring accurate positioning, alignment, and secure clamping of steel components is crucial for maintaining quality and structural integrity. This requires skilled operators, specialized welding equipment, and precision tooling.

How Do Magnetic Grippers Solve These Problems

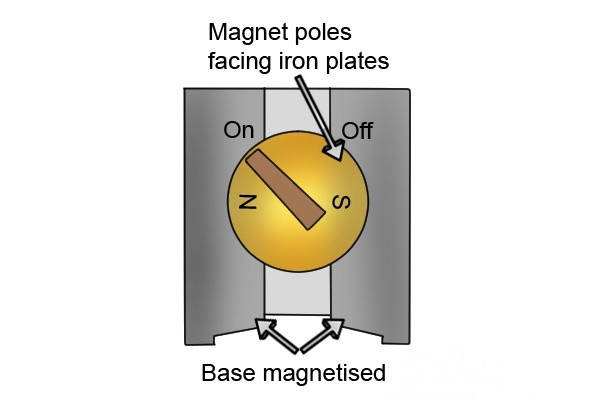

Constant Magnetic Force: Electro permanent magnetic grippers consume power only during the magnetization and demagnetization process. They are designed with fail-safe features to ensure a secure grip on the material, even in the event of a power failure. Moreover, the quick magnetization and demagnetization process of these grippers simplifies the handling process and makes it safer for workers.

Easy integration: They can be easily integrated into existing production lines or automated systems, making the installation process simpler and more convenient.

Longer Lifespan: Compared to traditional electromagnets, electro permanent magnetic grippers require minimal maintenance. They have a longer service life, as they have fewer moving parts subject to wear and tear.

Flexibility: Each magnet module can be controlled separately. This individual control allows for more flexibility and customization in gripping applications. This provides the opportunity for selective or sequential gripping. You can activate or deactivate specific modules as needed, depending on the size, shape, or orientation of the material being handled. This selective gripping capability enhances efficiency and adaptability in material handling operations.

Magnetic Grippers Recommendation

Electro permanent magnetic grippers offer the benefits of energy efficiency, safety, versatility, flexibility, precision, easy integration, and reduced maintenance, making them a compelling choice for material handling in various industrial applications.

It’s advisable to customize your magnetic grippers according to the specific material handling requirement. For more information, please contact HVR MAG at export@hvrmagnet.com