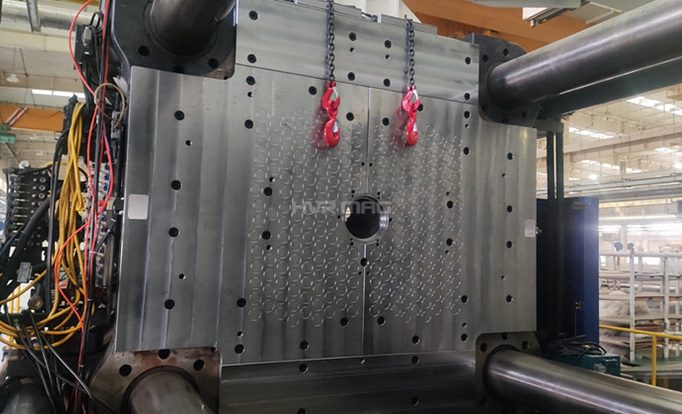

Magnetic Grinding Table

The magnetic grinding table is a grinding machine accessory. It is mounted on the grinding table and enables you to clamp and release workpieces quickly. Magnetic clamping prevents damage to the surface of the workpiece, which is important for grinding processes with high precision requirements.

Features of the magnetic grinding table

High precision: the magnets adsorb the workpiece in a flat surface with uniform forces. No deformation and wear, which contributes to high grinding accuracy.

High efficiency: easy to operate and accurate positioning. Clamping and releasing the workpiece takes only a few seconds, increasing machining efficiency.

High safety: the magnetic grinding table has a uniform and powerful clamping force, which prevents workpieces from coming loose or flying out. This ensures safe machining.

Large machining space: The magnetic grinding table only attaches to the bottom side of the workpiece, with no obstruction on the side of the workpiece, leaving plenty of space for grinding.

HVR MAG offers you high quality electro-permanent magnetic chuck for grinding machine. EPM magnetic grinding table offer other advantages in addition to safety and efficiency. There are currently three types of magnets available for magnetic grinding machines: electromagnetic, permanent magnet and electro-permanent magnet. The different working principles of the three lead to differences in their effectiveness as magnetic grinding table.

Electric permanent magnets save 95% of electricity compared to electromagnets. Because electromagnets rely on internal coils to be energised to produce a magnetic field, they require a continuous power supply to maintain their magnetism. Therefore electromagnetic chucks are only safe to use for a short period of time. Once they have been used for a long time, they will build up a lot of heat, which will reduce the magnetic strength and increase the likelihood of displacement and loosening of the workpiece. It may also lead to heat distortion of the workpiece.

This problem does not occur with electro permanent magnets. This is because the EPM only uses an electric current to act as a magnetic switch. The magnetic field coming from the permanent magnetic material inside. This means that the electro-permanent magnet chuck only uses electricity at the moment of clamping and releasing the workpiece. This is why using an electro permanent magnet saves 95% of the electrical energy compared to an electromagnet. You can disconnect the power supply after the workpiece has been clamped.

At the same time, the control of an electro-permanent magnet is more intelligent than that of a permanent magnet. The magnetic range and strength of the EPM chuck can be adjusted to suit a wider range of workpiece shapes and sizes. This is why a magnetic grinding table made of electro-permanent magnets is the most recommended choice.

Precautions when using the magnetic chuck on grinding machine.

- A thorough inspection of the machine should be carried out carefully before driving. Including inspection of the manipulation mechanism, electrical equipment and magnetic suction cups and other clamps. After inspection and then lubrication, carry out a test run after lubrication and confirm that everything is in good order before using.

- When mounting the workpiece, pay attention to the correctness and tightness of the card. As loosening the workpiece during grinding can cause serious consequences such as the workpiece flying out and injuring people or breaking the grinding wheel. At the beginning of the work, adjust the grinding wheel by hand so that it is closer to the workpiece slowly and the feed is small at the beginning. When it is necessary to use a stopper to control the reciprocating motion of the table, adjust it accurately according to the grinding length of the workpiece and fasten the stopper.

- Workers should wear protective glasses at work and dress grinding wheels in a balanced manner to prevent impact. Measuring workpieces, adjusting or wiping the machine tool should be done after stopping. When using a magnetic suction cup, the disc surface and workpiece should be cleaned, tightened and sucked firmly. And a stopper can be added if necessary to prevent the workpiece from shifting or flying out. Pay attention to the installation of wheel guards or machine block, and stand sideways over the front of the high-speed rotating grinding wheel.

- Avoid knocking or hitting the magnetic grinding table. Ensure that the table surface is clean and free of oil.

For more information, please feel free to contact us.