Lifting Magnet Safety Guidelines & Factors from Lifting Magnet Manufacturer – HVR MAG

In workplace or factories that works with ferrous materials or products, lifting magnet safety is gaining increasing importance and emphasis as lifting magnets are one of the most versatile and useful below-the-hook lifting devices used. Lift magnets are becoming the preferred way of moving things around and are able to handle immense weights with reduced human intervention. Hence improving the safety standards of lifting magnet operation brooks no delay.

Accidents can occur at any time, especially during the lifting, moving or transferring of a heavy load. And the consequences could be severe, damaged machinery, infrastructure, wounded personnel or injuries. However, the majority of accidents are caused by a failure in the execution of the lifting magnet safety protocols, either due to lack of maintenance of the lift magnets, or by making these magnetic lifting devices work beyond their lifting capacities. Therefore, knowing specific guidelines for the safe use, evaluation, and operation of these magnets is very important.

Lifting Magnet Safety Guidelines for Environment & Personnel

- Read and understand all instructions before operating any lifting magnet

- Only authorized personnel can operate the lifting magnets

- Always inspect thelifting magnet before and after using it – any slight issue with the equipment could be dangerous if left unattended for any period of time

- Bear in mindthat any lifting must have 3:1 safety factor

- During the lift, stay clear of the work load

- Never stand below a lifting magnet or any lifting device carrying a load because of the potential for a dropped load.The rule of thumb is to stay out of the path of the overhead magnet as it transports loads from one area to another

- Pay close attention to the load until it has been safely

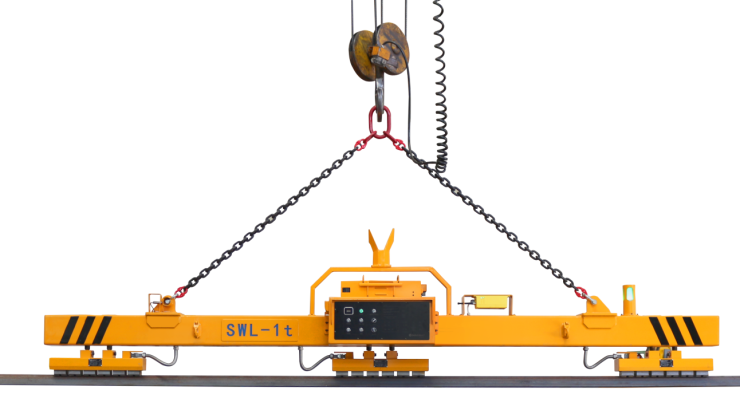

- Use a spreader bar(lifting beam) hanging two or more lifting magnets to lift big plates

- Always gently and smoothly lift, move and lay down the lifting magnet and load without sudden acceleration and deceleration.

Lifting Magnet Safety Factors

- Load Material. Be sure the load to be lifted is made of ferrous materials. Alloys may not be as magnetic as low-carbon steel.

- Load Surface Condition. Make sure the load surface clean – if necessary remove dust, burrs, unnecessary paints and chips from it. Elements of rust, dirt, ice, snow, oil, or paint are all considered to be an air gap that creates a weaker pulling force. Make sure the full surface of the magnet is in contact with the material.

- Load Weight. Be aware of the lifting capacity of the lifting magnet and comply to this limit– never, for any reason, exceed this limit.

- Load Thickness. Thinner materials are more challenging to lift than thicker materials because thinner materials can’t accept all the lines of force, resulting in reduced capacity. This is not a linear function. For example, if a magnet’s full capacity is needed to pick up 10mm-thick steel plate, that doesn’t mean that half the magnet’s capacity can pick up 5mm-thick material.

- Load Temperature. Operate the lifting magnet at temperature within its maximum value, which means the material temperature should NOT EXCEED the recommended maximum temperature for lifting magnets. They can lose strengthif working under extremely high temperature.

Failing to obey relevant operation rules, or operating lifting magnets that have not been inspected before use, even a minor lapse in operating procedure, may cause dropping of heavy work load, which would result in personal injury or even death as well as property damage. Hence, the above mentioned lifting magnet safety rules must be kept in mind and observed in operating the magnetic lifting device, especially for workers.

Lifting Magnet Safety Carer – HVR MAG, Manufacturer

All HVR MAG‘s lifting magnets are custom designed and engineered upon client’s applicational requirements. We offer ont only magnetic lifters, but also below-the-hook lifting beams. Most often clients would request a whole set of magnetic lifting deivce – lifting magnets equipped on beam.

We incorporate magnetic lifting beam with lifting magnet safety considerations during the design and manufacturing process. Featured with Superior Safety and Energy Saving, contact us to get a tailored magnetic lifting solution.