Custom Magnetic Grippers from HVR MAG

Why are they are Popular among Structural Fabrication and Construction Machinery?

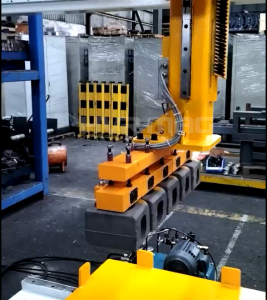

A gripper is a robotic arm tool used to lift, hold, position, or transfer workpieces repeatedly. In recent years, more and more automated production lines have adopted electro-permanent magnetic grippers. HVR MAG, specializing in electro-permanent magnet technology and products, has offered lots of custom magnetic grippers for many manufacturing enterprises. One big reason is that our custom design can meet the requirements of different working conditions.

The design of magnetic grippers should have the following characteristics:

1. Simple and firm positioning or clamping.

2. Automatic adjustment of the magnetic force according to the demand when handling.

3. Customization according to the customer’s specific needs, say workpieces with high temperature or special shapes.

4. PLC intelligent control throughout the process, with no need for human presence. An unmanned intelligent production line is possible.

5. Strong magnetic force, safe and reliable. It helps to achieve high production efficiency.

6. The magnetizing and demagnetizing time is only about 0.6 seconds, realizing a fast cycle.

7. Magnetic grippers are small-sized, and flexible enough that can be equipped with different industrial robots. Say articulated robots, truss robots, palletizing robots, and welding robots.

At present, large domestic enterprises such as Sany, Zoomlion, Fanuc, Weihua, Zhenhua Port Machinery, etc. have adopted HVR Magnetic grippers for ferrous metal handling. Mainly because HVR MAG has accumulated technical professionalism capabilities and industry confidence through many years of research and development. We’re leading the industry in China.

Except for custom magnetic grippers, HVR MAG also produces lifting magnets. And lifting magnets, also the main product, are used in heavy industries of steel mills, structural fabrication, shipbuilding, metalworking, wind power machinery, etc. What’s more, we also manufacture magnetic mold clamping systems for quick mold change in plastic injection molding. Anything you are interested in? Contact us now at: export@hvrmagnet.com