The Benefits of Integrating Electro Permanent Lifting Magnets into Automated Manufacturing Processes

In today’s rapidly evolving manufacturing industry, automation plays a pivotal role in improving efficiency, productivity, and overall operational performance. One such automation solution that has gained significant traction is the integration of electro permanent lifting magnets. This article explores the benefits of incorporating these magnets into automated manufacturing processes.

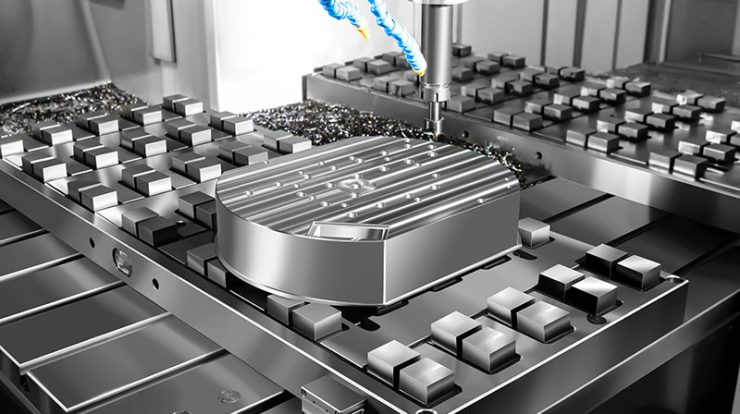

Handling Capabilities of Electro Permanent Lifting Magnets

The integration of electro permanent lifting magnets brings notable advancements in handling capabilities. With individually controlled grippers, these magnets allow for the handling of single steel plates under room temperature automatically and semi-automatically. This is a set of magnets, using the example of intelligent overhead cranes with 96 electro permanent magnetic grippers utilized in the shipbuilding industry. The ability to handle such heavy loads, up to 6 tons, showcases the robustness and reliability of these magnets. This eliminates the need for manual labor in the handling process, reducing the risk of accidents and improving overall operational safety.

Improved Efficiency and Productivity

By integrating electro permanent lifting magnets into automated manufacturing processes, significant gains in efficiency and productivity can be achieved. The magnets enable faster and more precise handling of steel plates, reducing production downtime and increasing throughput in shipbuilding operations. This results in improved productivity and a more streamlined production process.

Reduced Labor Costs and Workforce Optimization

With the integration of electro permanent lifting magnets, there is a considerable reduction in labor costs associated with manual material handling. These magnets eliminate the need for manual work, minimizing the risk of injuries and workers’ fatigue. By automating the handling process, companies can optimize their workforce and allocate labor to more value-added tasks, further improving operational efficiency and cost-effectiveness.

Enhanced Safety Features of Electro Permanent Lifting Magnets

Safety is of paramount importance in manufacturing environments. Integrating electro permanent lifting magnets into automated processes ensures enhanced safety features. These magnets incorporate fail-safe mechanisms such as sensors and diagnostics, ensuring secure and reliable operations. The individual control of each gripper provides precise and controlled handling, minimizing the risk of accidents and damage to the materials being lifted. Additionally, the magnets can detect anomalies and automatically stop operations to prevent potential hazards.

Flexibility and Adaptability of Electro Permanent Lifting Magnets

The integration of electro permanent lifting magnets offers flexibility and adaptability to changing manufacturing needs. As they can be individually controlled, the magnets can be adjusted to grip different sizes and types of steel plates, facilitating diverse manufacturing requirements. This adaptability allows for efficient switching between different product lines, reducing setup times and increasing overall operational agility.

Conclusion

The integration of electro permanent lifting magnets into automated manufacturing processes offers numerous benefits for industries such as shipbuilding. The enhanced handling capabilities, improved efficiency and productivity, reduced labor costs, enhanced safety features, and flexibility make these magnets a valuable investment in today’s competitive manufacturing environment. Embracing automation technologies like these helps manufacturers stay at the forefront of innovation while achieving operational excellence. For more information, please contact HVR MAG at export@hvrmagnet.com