8 Must-Have Excavator Attachments

Keywords: types of excavator attachments, attachment for excavator, hydraulic hammer breaker

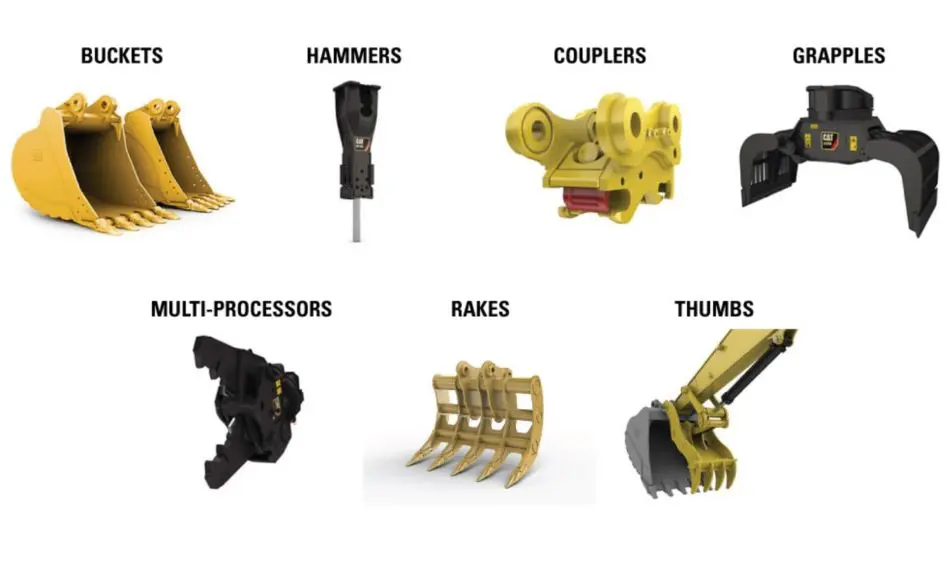

Types of excavator attachments

Excavator attachments come in various forms, and the world of excavation has seen its fair share of homemade and unique creations. From DIY enthusiasts crafting their homemade excavator attachments to manufacturers designing unique mini excavator attachments, the possibilities are endless. These attachments can transform an excavator into a versatile powerhouse, enhancing its capabilities for specific tasks. Whether it’s a custom-built attachment or a purpose-made one, the right attachment for an excavator can unlock new levels of efficiency and productivity, making it a valuable tool in the construction and earthmoving industry.

Despite its name, excavators aren’t just good for excavating …they can be used for cutting undergrowth, digging holes, sorting material and so much more. DAVE BULLARD gets the word on some of the industry’s recommended excavator attachments…

The hydraulic excavator has been a real game-changer for the construction, earthmoving, mining and quarrying industries since its introduction in the 1960s, not least due to its ability to tackle a wide variety of tasks with a simple change of attachment.

This ability is not always exploited, as many people still think of an excavator simply as a machine with a bucket used to dig and move earth. So we asked a few industry stalwarts – Queensland Rock Breakers (QRB) general manager, Fred Carlsson; Digga Australia marketing manager, Lionel Smitka; and Delecca’s sales manager, Jason Delecca – to name their top recommended excavator attachments.

We’ll crown the digging bucket as champion because it’s both ubiquitous and indispensable. Then all three of our experts had rock breakers and hydraulic grabs on their lists, with vibrating compaction plates, flail mowers and sieve buckets appearing on two lists.

“As you get into the specialist fields, the must-have attachments depend on your application,” Carlsson pointed out.

“There are a number of attachments such as pile drivers and rock saws that probably don’t make the list because of their limited overall applications but, as you can see, there is no shortage of attachments, which is one reason why excavators account for roughly half the machinery market in Australia.”

We take a look at each expert’s must-have list, then examine eight attachments in more detail:

Frederik Carlsson – Queensland Rock Breakers (QRB)

- Rock Breaker

- Digging buckets

- Static attachments – compaction wheels, rippers, mud buckets, sieve buckets, trenching buckets, and rock buckets

- ALLU Transformer processing bucket

- Vibrating rippers

- Rotary twin-head cutters

- Vibrating compaction plates

- Planers and Profilers

- Crushers and pulverisers

- Grabs

Lionel Smitka – Digga Australia

- Post hole borer

- Trencher

- Rock breaker

- Grabs

- Flail mower

- Mulcher

Jason Delecca – Delecca’s

- Flail mower

- Hydraulic grab

- Vibrating plate

- Trench compactor

- Sieve bucket

- Rock Breaker

- Auger Drive

Flail Mower

A flail mower is a versatile agricultural or landscaping equipment that uses rotating blades or flails to effectively cut and mulch vegetation. It excels in handling rough terrain, thick vegetation, and provides a mulching effect for weed control and soil nutrition. Ideal for fields, orchards, and roadsides, flail mowers offer efficient cutting performance and can be attached to various vehicles or machinery for different applications.

Hydraulic Hammer Breaker

A hydraulic hammer breaker is a powerful attachment used with excavators and other heavy machinery. It utilizes hydraulic power to deliver high-impact blows, making it ideal for breaking through hard surfaces like concrete, rock, or pavement. With its robust construction and precise control, a hydraulic hammer breaker provides efficient and precise demolition capabilities, allowing for quick and effective removal of obstacles and structures. It is a valuable tool in construction, demolition, and mining industries, enhancing productivity and reducing manual labor.

Hydraulic Quick Coupler

A hydraulic quick coupler is a convenient attachment for excavators that enables rapid and effortless interchange of various tools and attachments. With its hydraulic actuation, it allows operators to swiftly connect and disconnect buckets, breakers, grapples, and other implements without leaving the cab. This time-saving device enhances efficiency, reduces downtime, and improves job site safety by eliminating the need for manual attachment changes. The hydraulic quick coupler is a valuable addition to excavators, streamlining workflow and maximizing productivity in construction, landscaping, and earthmoving applications.

Excavator grapple bucket

An excavator grapple bucket is a versatile attachment that combines the functionality of a bucket with the gripping power of a grapple. It is designed to handle various materials, such as logs, rocks, debris, and other bulky items. The grapple bucket features strong, interlocking teeth or claws that securely grasp and hold objects during lifting and transport. With its ability to grab and release materials quickly and efficiently, the excavator grapple bucket is an invaluable tool for forestry, construction, and waste management applications, enhancing productivity and versatility on the job site.

Hydraulic shear

A hydraulic shear is a powerful attachment used in demolition and scrap metal processing. It utilizes hydraulic force to cut through thick and heavy materials, such as steel beams, pipes, and plates. With its sharp blades and immense cutting strength, the hydraulic shear delivers precise and efficient cutting performance. It enables operators to quickly dismantle structures and process large metal components for recycling. The hydraulic shear is a vital tool in the construction, demolition, and metal recycling industries, providing a safe and efficient solution for cutting and processing heavy-duty materials.

Hydraulic Magnet

A hydraulic magnet is a specialized attachment used in material handling applications, particularly for collecting and moving ferrous metal objects. Powered by hydraulic systems, it generates a magnetic field that attracts and lifts metal materials, such as iron, steel, and scrap. The hydraulic magnet simplifies the cleanup process by efficiently collecting and separating metal debris from other materials. It is commonly utilized in recycling facilities, scrapyards, and construction sites to improve efficiency, reduce manual labor, and enhance safety during metal handling operation.

For more information about types of excavator attachments, please look at hydraulicmagnet.com.