What is an excavator? What is it made of?- Hydraulic Magnet

Keywords: hydraulic scrap magnet, excavator auger attachment, mini excavator buckets

hydraulic scrap magnet

Excavators are a family of heavy earth moving machinery that are primarily used in ‘digging’ or ‘excavation’ of earth & rock and are some of the most common pieces of equipment found in construction projects and mines. In simple terms, they are the mechanized versions of the plain old shovel. Here is the Merriam-Webster’s definition.

The modern mechanized excavators are mostly called “Hydraulic Excavators” due to their utilization of hydraulic power to excavate earth.

Depending on their application, excavators differ in sizes and operating weights ranging anywhere from a few thousand kilograms (a few thousand pounds) to a million kilograms (few million pounds). Because of their diverse nature, there are different types of excavators. For example, the smallest of excavators are called mini excavators or compact excavators while the largest excavators are usually mining excavators because of their primary application in mining job sites.

Excavators are heavy duty versatile machines. They have been found to be so essential in the state of modern construction and mining. They also differ from the regular backhoe by their size and versatility. Some of the tasks that excavators perform for you include excavating earth, digging trenches, driving piles, demolition projects and many more.

What are the core building blocks of an excavator?

The standard excavator is primary made of 3 key segments or systems:

- The Main body or the House

- The Undercarriage

- The Arm

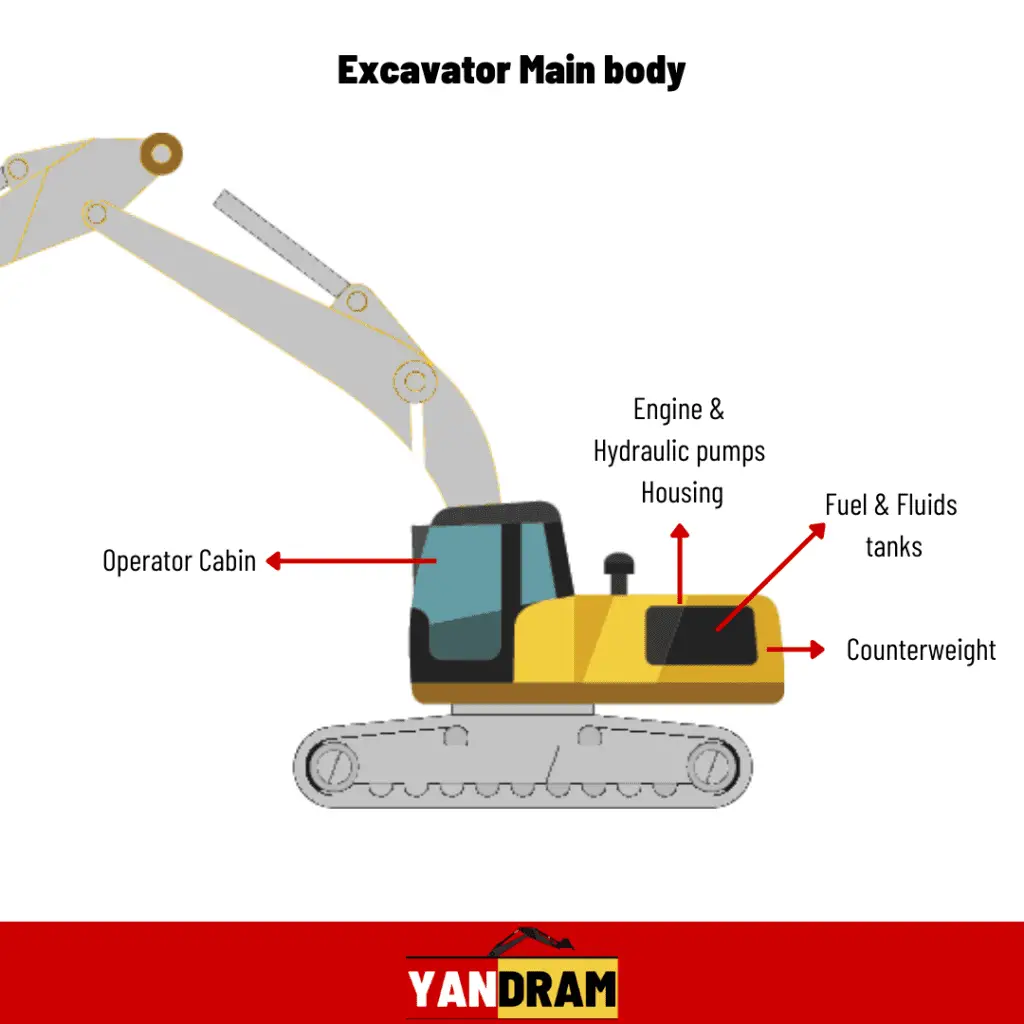

What is the Main body or the House of an excavator?

The main body of the excavator is called the “house” as it houses all its key components. The main body of the excavator consists of the following constituent parts:

Operator cabin:

The operator cabin or the “cab” houses all the controls for the operator. Most modern excavators have the latest safety technology in place including Roll-Over-Protection System (ROPS) and multiple other in-cabin safety features. The cab is also designed to keep the operator comfortable when operating the machine.

Engine:

The engine is the most complex and expensive part of the excavator. The technology and reliability of the engine decides the competitive position of the excavator in the market. Depending on the application and size of the excavators, the engine power can vary from few kW (or a few HP) to a few thousand kW (or a few thousand HP).

Hydraulic Pumps:

The hydraulic pump is also encased in the house. Excavators can have one or more hydraulic pumps which will be used to deliver power from the engine to all hydraulic cylinders in the arm, the swing motor and the final drive in the undercarriage

Operator cabin:

The operator cabin or the “cab” houses all the controls for the operator. Most modern excavators have the latest safety technology in place including Roll-Over-Protection System (ROPS) and multiple other in-cabin safety features. The cab is also designed to keep the operator comfortable when operating the machine.

Engine:

The engine is the most complex and expensive part of the excavator. The technology and reliability of the engine decides the competitive position of the excavator in the market. Depending on the application and size of the excavators, the engine power can vary from few kW (or a few HP) to a few thousand kW (or a few thousand HP).

Hydraulic Pumps:

The hydraulic pump is also encased in the house. Excavators can have one or more hydraulic pumps which will be used to deliver power from the engine to all hydraulic cylinders in the arm, the swing motor and the final drive in the undercarriage

Fuel, Hydraulic and other tanks:

These tanks serve as storage containers for fuel, hydraulic fluid, oils and other lubricants.

Counterweight:

The counterweight is the essential part of the excavator helping the excavator maintain equilibrium when lifting the load in its arm. The counterweight is primarily to help the excavator stay stable when digging.

mini excavator buckets

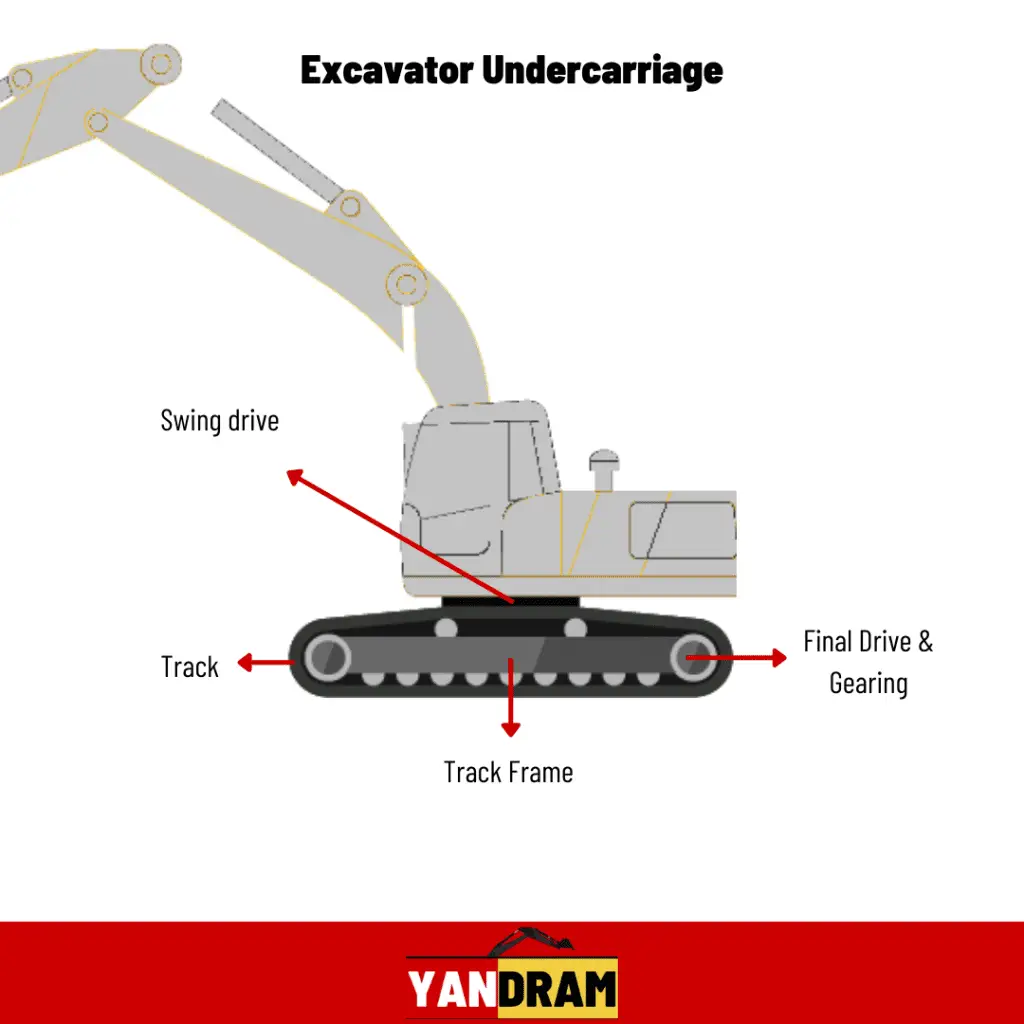

What is the Undercarriage of an excavator?

The undercarriage is the segment of the excavator providing all the mechanical movement required for the excavator. The undercarriage is connected to the center pin which effectively provides a rotating platform for the house. The undercarriage consists of the following parts:

Swing drive:

The swing drive enables the 360 degree rotational motion of the excavator cabin. The entire excavator house and arm rest on the swing mechanism which in turn rests on the track frame. The swing drive also ensures that the entire house of the excavator rotates along.

Track frame:

Track frame holds the entire weight of the excavator and is the primary load bearing body of the excavator

Tracks:

Tracks are the parts of the excavator which help move the excavator. Excavators with tracks are also called as Crawler Excavators or Tracked excavators. Crawler excavators come with different configurations for their crawler tracks. On the other hand, some excavators have wheels instead of tracks and are called “Wheeled excavators” or “Wheel Excavators”.

Final drive & Gearing:

The final drive is connected to the hydraulic motors and enables the movement of the tracks while the gearing ensures transfer of torque from the drive to the track

excavator auger attachment

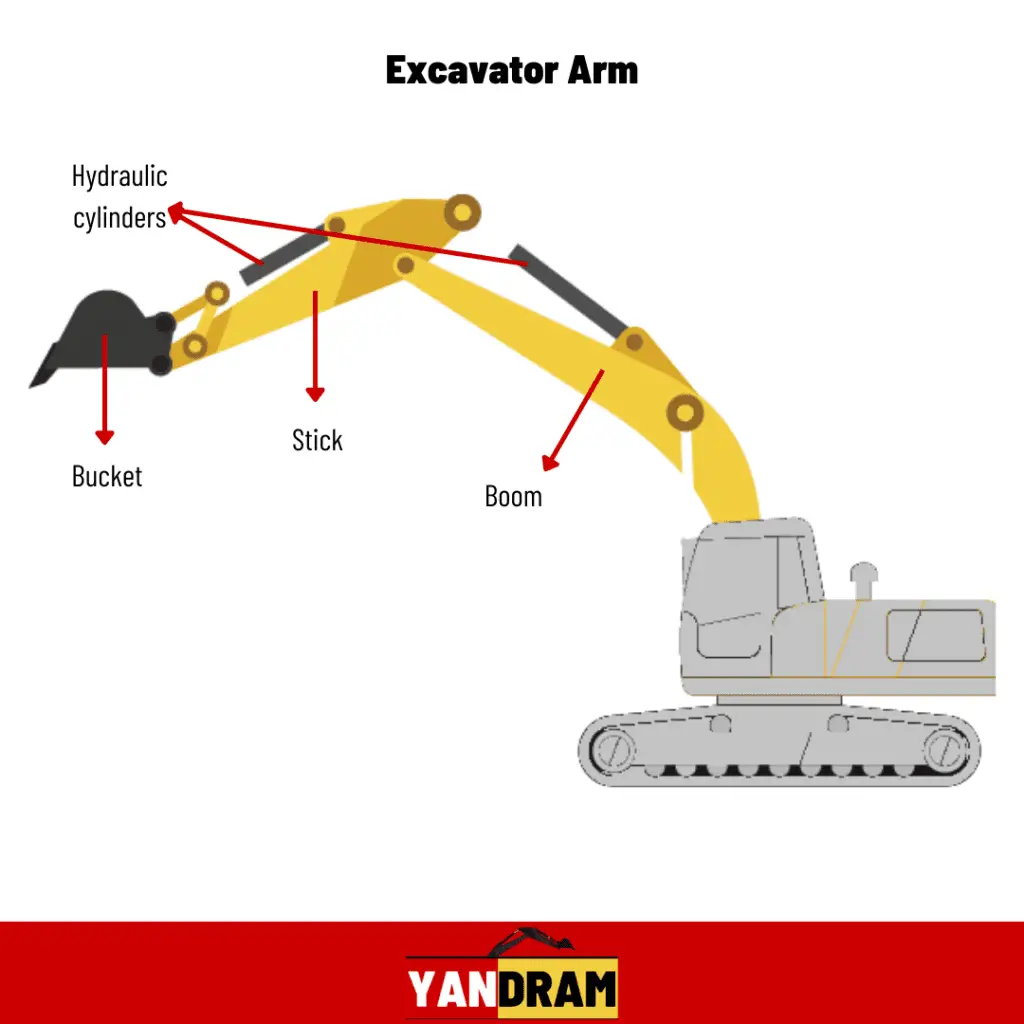

What is the Arm of an excavator?

The arm is the part of the excavator that does the core activity of “excavating” or any other depending on its attachment. The arm consists of the following parts:

Boom:

The boom is the part of the arm that acts the structural bulwark. It holds together the main body of the excavator with the stick and arm. The boom bears all the weight of the payload and distributes it evenly. The boom acts as the support for the up-down movement of the arm. Usually, most excavators carry a boom and bucket. However, given how versatile excavators are, you will also see excavators being used with many attachments.

Stick:

The stick holds the attachment and enables a digging motion by flexing the bucket.

Hydraulic cylinders:

These enable the movement of the arm. The arm can move in a typical digging motion (up-down and closer-farther) while the swing drive on the undercarriage enables circular movement of the excavator.

Attachment:

Attachments are usually buckets. But in modern excavators, buckets are also replaced by other sophisticated hydraulic attachments for special applications. Some of the common attachments other than buckets are trench cutters, augers, demolition hammers, crusher buckets, clamshell buckets, etc., To know more about excavator attachments, click here.

For the uninitiated, here is a wonderful promotional video from Volvo Construction Equipment showing Dolph Lundgren training a bunch of excavators. You may see all the sizes and shapes of excavators, from long-reach excavators to large excavators. Truly, excavator types are so diverse.

Conclusion

In summary, excavators are usually used in construction and mining industries for moving material and earth as required. They are some of the most numerous and most useful machines in the world, contributing to over 25% of the heavy equipment industry. Usually, manufacturers have multiple configurations or variants for each model of excavator to fit to every application or need. Excavators are also going through a technology revolution. If interested to know more, read here.

We have not covered other kinds of excavators like suction excavators and dragline excavators as they work on different principles.