How Does Magnetic Robot Gripper Facilitate Metal Bending Procedure

This article introduces a new way of loading and unloading metal strip for bending machine, industrial robots configured with bespoke magnet grippers. Let’s take a look at how magnetic robot gripper helps facilitate the pick and place of steel strip through the whole bending procedure.

First, let’s get acquainted with the process of bending metal.

Metal bending is a manufacturing process by which (sheet) metal can be deformed when applying force to the subject, which causes it to bend at an angle and form the anticipated shape, which often results in it being in a ‘V’ or a ‘U’ shape.

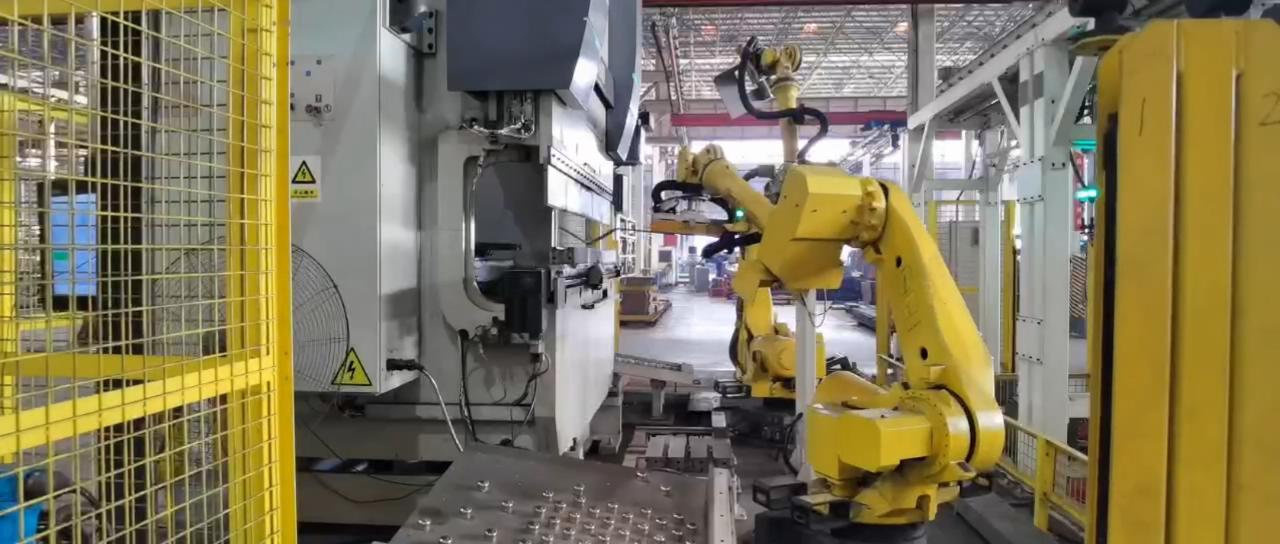

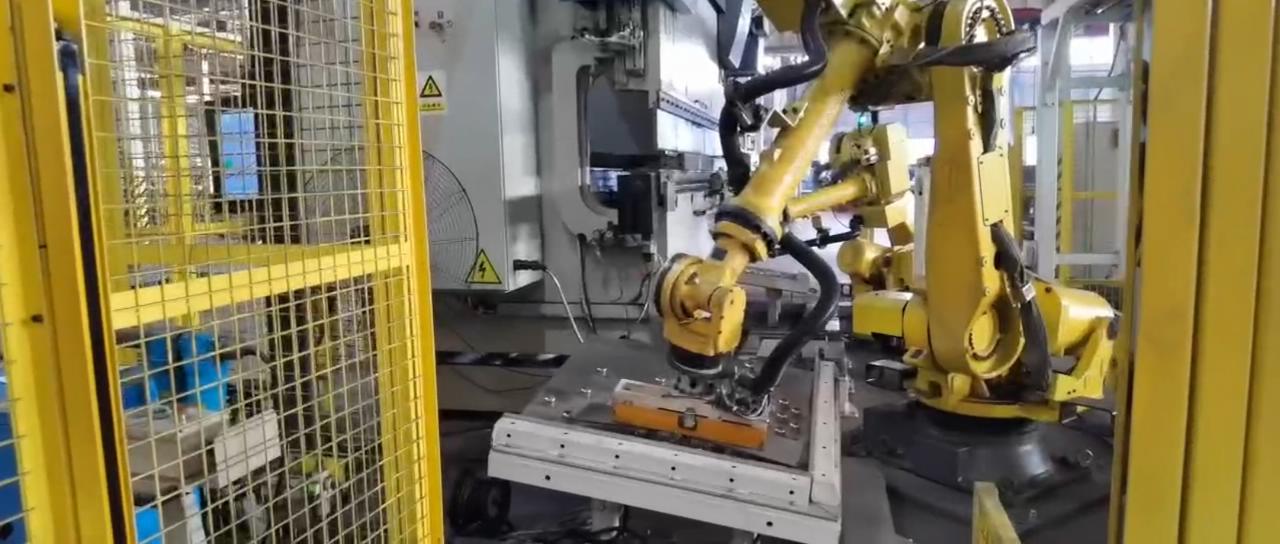

Below is an epitome of metal bending station in a workshop. The yellow industrial robots are responsible for the pick and place of steel strip before or after the bending procedure, utilizing the magnetic force released by electromagnetic robot gripper.

View the whole automatic loading and unloading process:

What Are the Purpose of Grippers in Robotics?

In the simplest terms, grippers are devices that enable robots to pick up and hold objects (like the magnetic gripper in above mentioned pictures). When combined with a collaborative (or ‘cobot’) industrial robot arm, grippers enable manufacturers to automate key processes, such as inspection, assembly, pick & place and machine tending.

Where Are Magnetic Grippers Used?

Magnetic grippers are used in a variety of industries where products or components contain ferrous metal. Latest applications of magnet grippers include material handling, palletizing, and bin picking of automobile parts and palletizing metal containers like paint and solvent cans and other steel containers.

Explain the working of magnet grippers used for robots:

The magnetic robot gripper, designed and manufactured by HVR MAG, uses a magnetized surface to grab metal items. The gripping head is magnetized/demagnetized by a momentous electric pulse. It consumes no power in gripping state. Only uses electricity in the magnetization and demagnetization phase.

Benefits gained with magnetic robot gripper:

✦Improves overall steel strip handling efficiency, namely the bending efficiency

✦Simple design and compact structure

✦Bespoke designed, PLC programmable

✦Precision handling of strip – picking up 1pc each time, without grabbing a second or multiple sheets

✦Good versatility – suitable for various ferrous metal wokpieces

Learn more about the property of our magnetic gripping technology, please refer to HVR MAG’s website:https://www.hvrmagnet.com/